Beveling Machine For Glass

A Beveling Machine for Glass is a specialized tool used to create beveled edges on glass panels, enhancing the aesthetic appearance and structural integrity of glass products. Beveling is the process of cutting the edges of a glass sheet at an angle, usually between 20 and 45 degrees, creating a smooth, sloped edge. This type of finish is commonly seen on mirrors, decorative glass, table tops, windows, and various architectural applications.

Key Features

-

Edge Polishing: Many beveling machines include polishing systems to smooth the beveled edges, providing a clean and shiny finish. This is particularly important for products like mirrors or high-end glass furniture, where aesthetic appearance is critical.

-

Adjustable Speed and Pressure: To optimize the beveling process for different glass thicknesses and types, many machines offer adjustable speed and pressure settings. This feature allows operators to fine-tune the machine for the best results on various glass materials.

-

Robust Build Quality: Beveling machines are built to handle heavy-duty workloads, ensuring durability and long-term performance. High-quality machines are constructed with materials that can withstand the abrasiveness of grinding and polishing processes.

-

Safety Features: Beveling machines are designed with safety features such as protective covers, emergency stop buttons, and safety sensors to prevent accidents. The use of automatic and controlled systems reduces the chances of human error and injury.

-

Versatility: Beveling machines can handle a wide range of glass sizes and thicknesses, making them versatile for various industries. Whether it’s small decorative glass or large architectural panels, the machine can be adjusted to meet specific requirements.

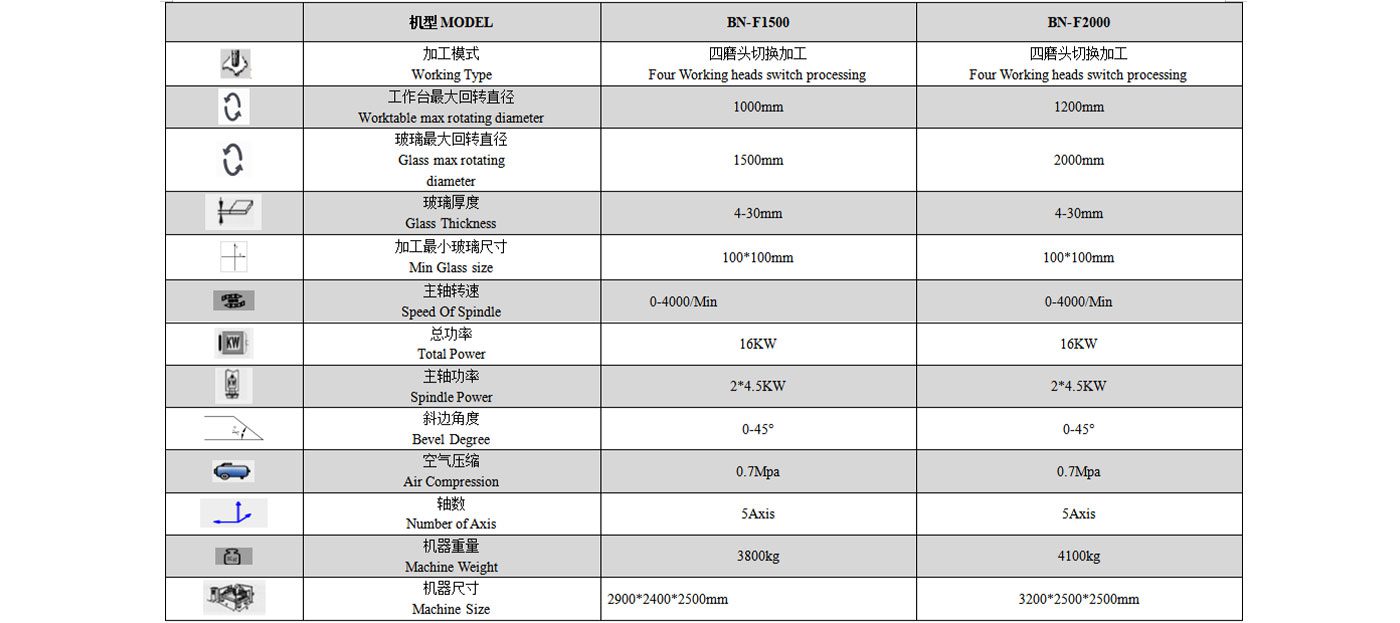

Technical Specifications

- Processing Thickness: 3mm – 25mm

- Bevel Width: 0mm – 40mm

- Processing Speed: 0.5 – 6 meters/minute

- Power: 15kW

- Control System: PLC control system

- Cooling System: Water cooling

A Beveling Machine for Glass is a type of industrial equipment designed specifically to bevel the edges of glass sheets. It uses abrasive tools like diamond or silicon carbide wheels to grind and shape the edges of the glass, producing a smooth, slanted edge that not only adds a decorative touch but also strengthens the glass.

These machines come in various types, from manual models for small-scale production to fully automated machines that can process large volumes of glass with high precision. Beveling machines may also be equipped with additional features such as polishing tools, edge finishing capabilities, and CNC controls to ensure consistency and quality.

Advantages of Beveling Machine for Glass

-

High Precision and Consistency: Beveling machines, particularly those with CNC controls, offer high precision and consistency across all glass pieces. This ensures that every product has the same high-quality finish, making them ideal for industries where uniformity is essential, such as in interior design and architectural applications.

-

Increased Productivity: The automation and efficiency of beveling machines enable high-speed production, reducing the time required for manual beveling processes. This results in faster turnaround times, making it easier for businesses to meet tight deadlines and fulfill large orders.

-

Improved Glass Aesthetics: Beveled edges enhance the visual appeal of glass products, creating a polished, professional look. Whether it’s for mirrors, glass tabletops, or custom glass panels, beveling adds an elegant touch that improves the overall aesthetic of the product.

-

Edge Strengthening: Beveling not only improves the look of the glass but also strengthens the edges, reducing the likelihood of breakage or chipping. This is particularly important for safety applications, such as in the automotive and architectural industries, where structural integrity is critical.

-

Higher-Quality Finish: Beveling machines are capable of producing high-quality, polished bevels that would be difficult to achieve through manual processes. This is especially important for high-end glass products that require a pristine finish for both functional and decorative purposes.

-

Safe Operation: With integrated safety features, beveling machines reduce the risk of injury and breakage, ensuring a safer working environment for operators. The automatic feeding and cutting mechanisms further reduce human interaction with hazardous equipment.

Why Choose Our Beveling Machine for Glass?

Beveling machines are highly customizable to meet specific production needs. Whether you require different bevel angles, edge profiles, or polishing finishes, the machine offers the flexibility to adjust parameters for a wide range of glass products. While the initial cost of a beveling machine may be substantial, the long-term savings come in the form of reduced labor costs, minimized waste, and increased production speed. Businesses can achieve higher throughput and meet customer demands faster while maintaining high product quality.

Technical Parameter