Decorative Glass Beveling Machine for Mirror Edges: Uses

2025/05/16 By admin

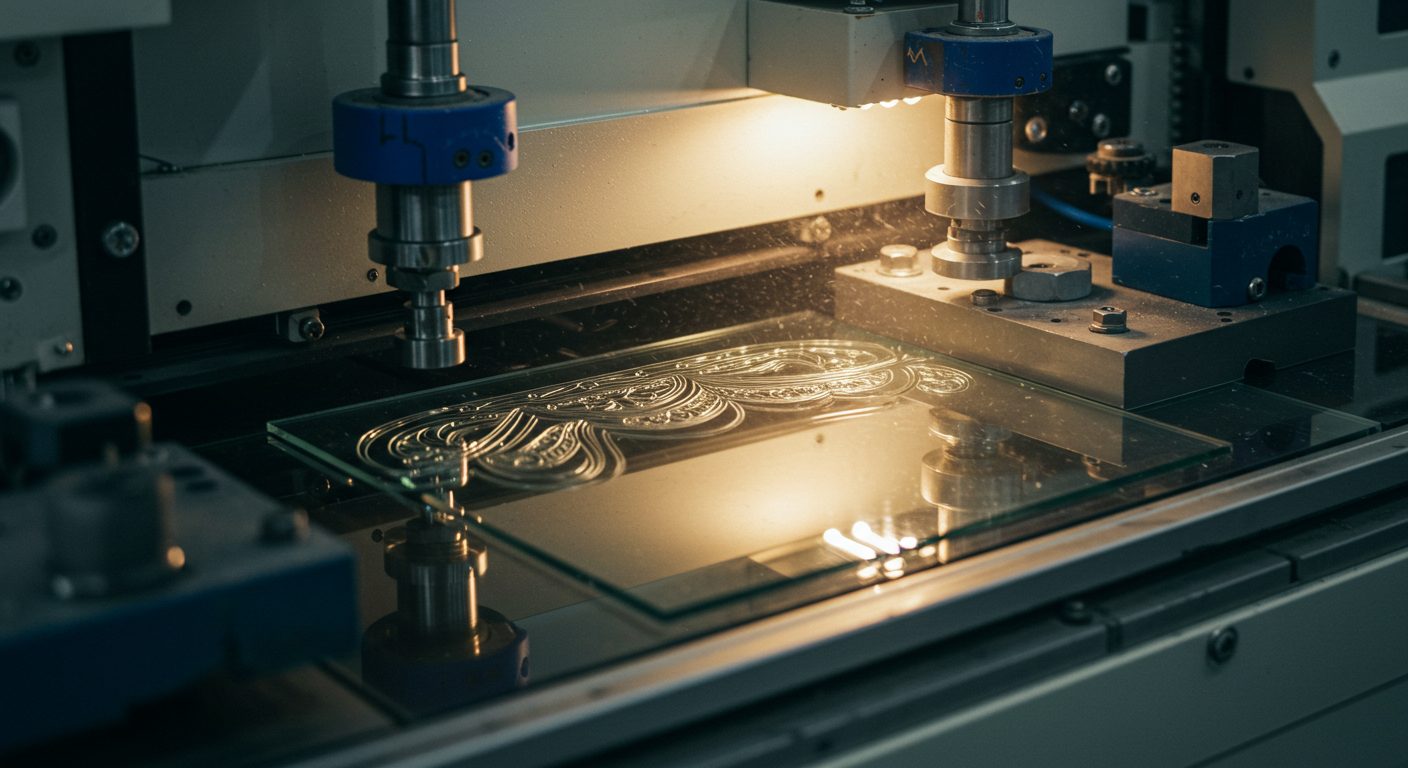

What is a Decorative Glass Beveling Machine?

A decorative glass beveling machine in any glass processing workshop is an accessory that bevels glass edges with a predetermined angle. The cuts are polygonal, and polishing is done meticulously so that the light achieves the best illumination possible for the object. As the light does further reflect and refract through the glass, polished surfaces of sandblasted glass will be formed, and the glass will be sandblasted for added strength and durability.

Main Functions:

• Performing glass polishing and contouring.

• Generating variable angles (most commonly between 3°–45°).

• Improving aesthetics for ornamental purposes.

These Machines Find Primary Application in:

• Mirrors with decorative beveling.

• Architectural glass elements.

• Glass tabletops and doors.

• Sculptures.

A 2025 Guide to Precision, Art, and Automation

The decorative glass beveling machine stands at the nexus of contemporary glass chic. It doesn’t matter whether it is simple beveling on mirrors and calibrated patterned furniture glass, or complex architectural art glass panels; this gadget is critical. As we will see, unlocking the universe of decorative glass beveling involves understanding different intricacies of the machines and different glass processing requirements, along with making the right selection to suit your needs.

Key Characteristics of a Decorative Glass Beveling Machine

The functions of the glass beveling machine should not stop at glass cutting; quality and precision in finish must be equally pleasing. Regarding beveled glass for mirrors, doors, and furniture pieces, the following aspects must provide functionality as well as aesthetic value.

Features of Edge Polishing for Finish Excellence

Processes that consist of edge polishing as glass edge beveling machines, need to have an edge remarking craving glass edge. Glass possessing polished edges is increasingly in demand because polished edges make glass gleam, which is very desirable in high-end décor, architectural glass panels, and artistic elements. For example, ornamental beveled glass of superior grade must be polished and glazed. Clear objectives have been met, no steps to polish have been added to the workflow, and quality objectives have been enhanced, so polishing integrated machines improves the overall process.

- Flexible Speed End Pressure Adjustments

The automatic glass beveling machines have new features for regulating speed and pressure, which have been added in the latest models. This allows operators to change the settings concerning the thickness of the glass, the material, and the depth of the bevel.

- Durable and Assured Construction

Various heavy-duty materials are used to fabricate the industrial glass beveling machines to withstand the endless hours of grinding and polishing. The robust frame alone dampens a significant amount of vibration and other mechanical wear, allowing dependable operations under some of the most difficult conditions. The same is true for high-precision glass beveling machines that have to operate under rigid production schedules and at the same time deliver perfect bevels, which need a strong frame.

What are the Advantages of Using a Decorative Glass Beveling Machine?

A decorative glass beveling machine should be selected very carefully to maximize not only the beauty of the output but also the efficiency and smoothness of operations.

- Shifting Competition: The Use of CNC Machines as They Give Exceptional Quality for Each Bevel Produced

No one can beat CNC machines when it comes to accuracy. Each bevel or edge is set to the required size, angle, and amount of polish, which is very important in glass mixing art and crafts. Such uniformity guarantees uniform multiplicity sets, which are very important for design patterns in furnishings in interior design and architectural glass works.

- Advancement of Technology and Productivity of the Company

The manual work performed in a business may be optimized and automated to save costs, like time. In the case of glass edge beveling, profit and production will go to the next level, and automated systems will reduce labor costs, which are needed to complete larger orders in a set time. Also, the quality standards expected by the business are maintained.

- Increased Aesthetic Appeal

Besides usability, the beveled edges of glass have an embellishing role. These edges increase the light reflection of glass surfaces and make them seem more luxurious and three-dimensional. This also further enhances the value of beveled glass for:

• Mirrors

• Tabletops

• Cabinet insert

• Glazed doors and window sashes

The charm and worth of a product is said to increase enormously with intricate other finishing features like bevels.

Uses: When Elegance and Functionality Meet

The beveling of decorative glass makes these areas easier to work in due to the flexibility of a decorative glass beveling machine.

Interior and Furniture Design

• Beveled borders on a glass tabletop

• Glass decoration on the cabinet and wardrobe doors.

Architecture and Construction

• Facade glass panels

• Windows with ornamental edged glass designs include other etched patterns.

Automotive and Marine

• Carved curved panes for windows of specialty vehicles

• Decorative windows of yachts.

Art and Decoration

• Customized beveled mirrors for resorts, spas, and bathrooms.

A Complete Maintenance Report Can Be Accessed Here

The inflatable budget, complexity of designs, and volume of intended output dictate the type of decorative beveling machine to be acquired. From a small workshop to a large-scale manufacturer, the right equipment ensures productivity and quality.

1. Evaluate Your Production Volume

A straight-line glass beveling machine is best suited for the mass production of mirrored glasses or window panes due to its speed and uniform output. More complex designs are best accomplished using CNC glass beveling machines due to their versatility.

2. Glass Thickness and Bevel Angles

Confirm that the machine accommodates the glass thickness you normally work with. The range of angles for the bevels is between 3° and 45°, which allows for further artistic embellishments.

3. Reassess Spatial and Mobility Considerations

Occupational and ergonomic constraints of a user suggest that a portable glass beveling machine would be best suited for them. Increased productivity is observed at larger facilities with the use of double-head beveling machines.

4. Assess Brand Offerings, Maintenance, and Soft Support

From the analysis performed, supporting document maintenance, Telebahn-HK proved to boast long-term care along with spare parts support for their products.

Conclusion

The intricately designed glass beveling machines are more than just their components—they are a symbol of precision and elegance. Art and architecture enthusiasts are highly recommended to consider the most refined machining centers that will escalate their craftsmanship to an incredible level. For innovative products and professional assistance, visit BAINENG.

TRENDING POSTS

- Glass Shape Edging Machine Product Solution 2025/05/16

HOT TOPIC

- architectural glass beveling machine

- automatic glass beveling machine

- Automotive Glass Beveling Machine

- cnc engraving machine manufacturer

- CNC glass beveling machine

- cnc glass edge polishing machine

- CNC glass grinding machine

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machining Center

- decorative glass beveling machine

- glass beveling and polishing machine

- glass beveling equipment

- glass beveling machine distributor

- glass beveling machine for sale

- glass beveling machine manufacturer

- glass beveling machine price

- glass beveling machine supplier

- glass door beveling machine

- glass edge beveling machine

- glass edge chamfering machine

- glass edge finishing machine

- glass edge grinding machine

- glass edge polishing machine

- glass edge processing machine

- glass edge shaping machine

- glass edge smoothing machine

- glass edge trimming machine

- glass furniture beveling machine

- glass panel beveling machine

- Glass Shape Edging Machine

- glass window beveling machine

- mirror beveling machine