Glass Beveling Equipment for Sale: Explore a Wide Selection

2025/05/13 By admin

What is a Beveling Machine for Glass?

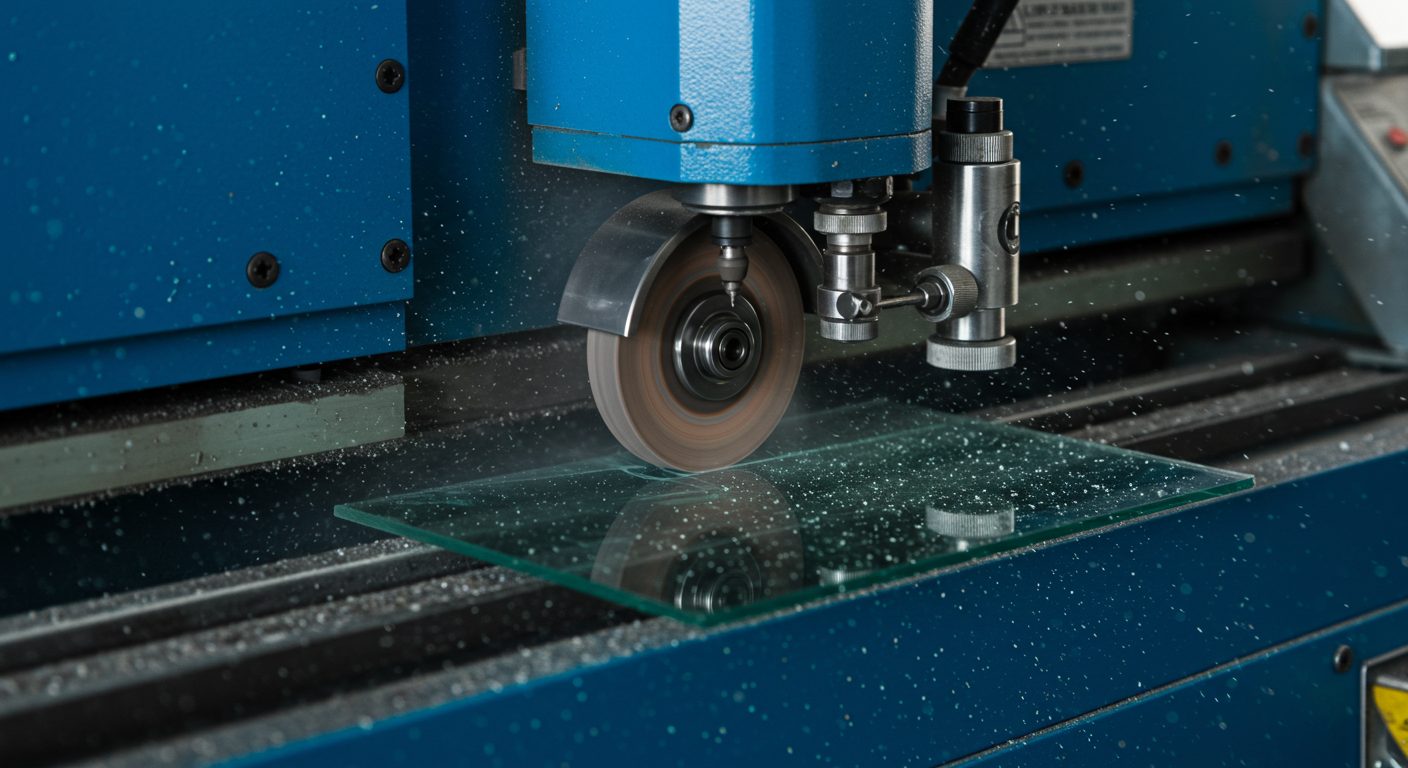

A powerful industrial-grade machining tool that cuts, shapes, and does polishing of glass panels is known as glass beveling equipment. The main purpose of glass beveling is doing beautify the glass and improve its safety by creating smooth and angled edges. This device assists in glass finishing, whether it is mirrors, architectural installations, furniture glass, or decorative glass panels.

Learning the Beveling Step

A range of both soft and hard materials, glass grade polished edges are placed on the bottom and top of the piece after cutting and shaping them to specified sizes. In this case, the edges of the corners were polished with smooth bevels. Also, the edge of the glass can be cut at sloping angles of not less than 45 degrees, which helps it glimmer beautifully. This pleasing feature helps the glass not only look beautiful, but also strengthen it. Some features are best suitable when purchasing a machine are:

– Easy Control System: The machine should provide simple or easy guidance.

– Super Polishing Systems: A lot of machines undertake polishing and beveling for a finer finish.

– Industrial Grade Polish: The materials used should be strong, making the machinery withstand tough conditions.

– Use of Touchscreens and PLC S: For easy alteration of devices if touchpad screens or computer systems are used.

Innovative Mastery in Precision CNC Glass Engraving

Innovative artists in the USA glass engraving, as well as CNC glass engraving and glass beveling, have a place to show off their skills as CNC machines have revolutionized the competitive arena of glass fabrication. Baineng works to integrate innovation and artistry with high-precision engineering so that you can design glass products for any industry application.

Use Cases of Glass Beveling Equipment

Modern glass beveling machines serve industries that require attractive finishes, safe edge treatment, and immaculate detailing such as mirror work. Whether it is flat glass, glass mirrors, or other decorative enhancements, with beveling, the product is aesthetically pleasant and functional.

1. Mirror Manufacturing

Beveled mirrors have class and beauty. They are manufactured by polishing and beveling the edges of mirrors, which increases their reflective value. This type of mirror is commonly used in hotels, luxury homes, and in modern interior design.

2. Architectural Glass Fabrication

Architectural glass includes curtain walls and internal partitions that require to be paneled with glass and have precise edge treatment. The glass used for construction and building decoration requires the use of straight line glass beveling machines and automatic bevelers.

3. Tabletop and Furniture Glass

Furniture glass processing consists of coffee tables, desks, and shelving units. CNC beveling machines across batches add consistency and repeatability to finishes. Chipping can be avoided while enhancing aesthetic appeal to edges with beveling.

4. Decorative and Art Glass Designs

Depth and texture for elaborate purposes like sculptures, lighting installations, or stained glass are assisted with beveling. These intricate tasks are best accomplished with portable beveling machines and manual bevelers.

Why Baineng Offers the Best Glass Beveling Solutions?

Baineng specializes in high-precision glass processing equipment, which includes glass 5-axis beveling machines with intelligent automation features. Our machining tools offer global technical support, straightforward CAM software, and quick setup. We provide tailored solutions from custom pieces to large-scale architectural glass.

Why Choose Our Beveling Machine for Glass | Glass Beveling Equipment?

With precise, speedy, and flexible results, elevating your production process is guaranteed when investing in our glass beveling equipment. Designed for a broad range of applications, our beveling machine for glass tackles everything from architectural-grade finishes to decorative glass edges. Complete control is offered over bevel angles, edge profiles, and polishing finishes, no matter the customization needed for beveled mirrors, furniture glass, or decorative panels.

- What makes our beveling machines stand out from the rest is their level of customization. Each glass beveling machine has CNC integration for fine cuts that guarantee repetition as well as precision accuracy. This flexibility ensures that design standards can be achieved by manufacturers without losing speed or quality.

- While the initial investment may seem significant, it pays off quickly. These machines streamlining repetitive tasks and minimizing defects dramatically increase productivity. The result is reduced costs and faster delivery, all while maintaining edge quality.

- Our beveling equipment’s glass is used globally by industry professionals and experts in mirror production, furniture manufacturing, and architectural glass designs.

Get a modern and yet reliable, efficient, and speedy glass edge beveling machine today.

Additional Considerations

Keep the following issues in mind while investing in glass beveling machines:

1. Number of Spindles

A machine’s ability is determined by the number of spindles it has. For example, a 9-spindle machine can perform rough and fine grinding alongside polishing in a single rotary.

2. Bevel Width and Angle

Width and angle measures of bevels fluctuating between 0°-45° may be altered according to the specifications of the project.

3. Compatibility With the Thickness of Glass

Please pay attention to the glass thickness that the machine works on, usually from 3mm up to 19mm.

4. Automation and Control Systems

Modern machinery is designed with PLC controls and touch screen interfaces, which enhance ease of use and accuracy.

Maintenance and Servicing

Long operational life and continuous delivery of the desired output are guaranteed through regular maintenance.

• Daily Inspection: Routinely check the mechanical, electrical, and pneumatic systems of the machine.

• Obsolete Item Disposal: Grinding wheels and coolant filters require prompt replacement.

• Washing and Oil Application: Excessive wear and tear is avoided by keeping parts clean and well-lubricated.

Choosing the Right Supplier for Glass Beveling Equipment

To guarantee dependable performance, long-term productivity, and satisfaction, specifically in after-sales service, choosing the right supplier for glass beveling equipment is of utmost importance. A good number of manufacturers exist, hence the need to select one that offers not just quality machines but also robust support.

Key Qualities

1. Experience and Reputation

Look for a supplier that uses trusted components. Glass machinery customer reviews, case studies, and certifications that indicate their credibility should also guide your choice.

2. After-Sales Support

Reduced downtime and smooth operation are possible through reliable after-sales services such as installation, training, maintenance, and availability of spare parts.

3. Customization Options

Every production line is unique, and hence the need for customization. Baineng is an example of a supplier with customizable beveling machines to meet specific requirements.

4. Global Reach and Delivery

Choose a supplier with global reach and responsive customer service, particularly if you are involved in international markets.

Conclusion

Acquiring the proper Glass Beveling Equipment implementation tools dramatically increases the quality of the product, improves operational efficiency, and increases customer satisfaction. Understanding the types and applications, along with the technical details, enables businesses to make decisions that align with their production objectives. Visit BAINENG.

TRENDING POSTS

- Glass Shape Edging Machine Product Solution 2025/05/13

HOT TOPIC

- architectural glass beveling machine

- automatic glass beveling machine

- Automotive Glass Beveling Machine

- cnc engraving machine manufacturer

- CNC glass beveling machine

- cnc glass edge polishing machine

- CNC glass grinding machine

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machining Center

- decorative glass beveling machine

- glass beveling and polishing machine

- glass beveling equipment

- glass beveling machine distributor

- glass beveling machine for sale

- glass beveling machine manufacturer

- glass beveling machine price

- glass beveling machine supplier

- glass door beveling machine

- glass edge beveling machine

- glass edge chamfering machine

- glass edge finishing machine

- glass edge grinding machine

- glass edge polishing machine

- glass edge processing machine

- glass edge shaping machine

- glass edge smoothing machine

- glass edge trimming machine

- glass furniture beveling machine

- glass panel beveling machine

- Glass Shape Edging Machine

- glass window beveling machine

- mirror beveling machine