Glass Beveling Machine for Sale: Affordable and Best Deals

2025/05/14 By admin

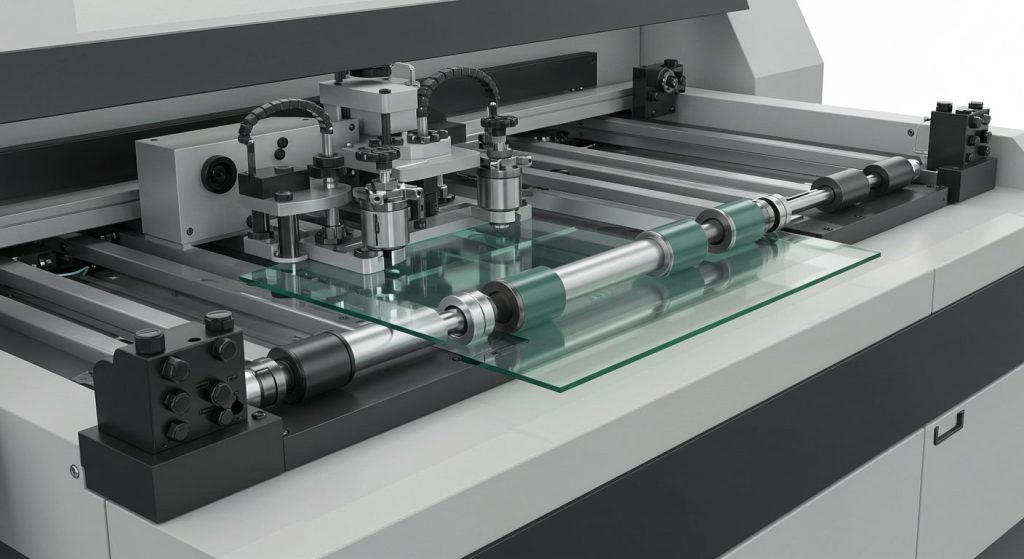

What is a Glass Beveling Machine?

Polishing and grinding of edges into beveled surfaces at a predetermined angle is done using glass beveling machines. Decorative glass manufacturing employs this extensively for mirrors, windows, tabletops, and architectural panels.

Considerable Features

⚬ Shaping edges

⚬ Smoothing and polishing

⚬ Corner chamfering

These devices can work with both 2D, 3D, and curved glass panels, depending on the control system.

Affordable, Accuracy-Crafted, and Powerful Glass Beveling Machine for Sale

We provide Baineng Machinery, the most trusted partner for glass processing, and offer them sharp, precision user user-friendly machines. We provide automatic straight-line beveling machines as well as multi-head glass edge polishing units. It is important to maintain precision in processes for the smooth functioning of operations, specifically for glass fabricators, architects, and furniture makers.

Why Choose a 5-Axis Glass Beveling Machine for Sale?

• Precision: Every five-axis movement ensures accuracy in bevel angles and seamless drives, even on contoured and irregular glass shapes.

• Productivity: Automation of the beveling process minimizes manual labor while increasing throughput.

• CNC Integration: Most models come with computerized control panels that allow users to program complex designs and retrieve them later.

• Flexibility: Suitable for straight, curved, and custom bevels, thus adding value in interior design, showrooms, and artistic works.

Benefits of a 5-Axis Glass Beveling Machine

While looking for a glass beveling machine for sale, it’s worth noting the technical advantages in terms of value to decide which model best fits your requirements. The 5-axis glass beveling machine is specially designed to deliver features that guarantee accuracy and productivity at the same time.

- Bevel Width

The machine supports up to 50 mm bevel width, which facilitates the making of deep and clear edges that are eye-pleasing and add elegance to glass pieces.

- Glass Thickness Range

Handles glass sheets from 3 mm to 25 mm, making it flexible for thin decorative pieces and thick structural glass.

- Multiple Spindles

With multiple grinding and polishing heads, it enhances the finish quality and decreases the processing time on glass pieces by providing smooth and clean edges from the first pass.

- Advanced Cooling System

To prevent overheating and guarantee safe operation, it is equipped with a water circulation cooling system that effectively maintains the machine’s temperature stability during prolonged use.

- Powerful Motor

This machine is powered by 3 kW to 5 kW motors, providing dependable, high-performance output during heavy-duty operation.

Technical Specifications – What Should You Look For?

When purchasing a glass beveling machine for sale, knowing the technical specifications is vital. These describe factors that influence performance, efficiency, and overall edge quality of the finished glass.

- Beveling Speed:

It is best to select machines that offer adjustable speeds within the range of 500 and 3000 RPM. While lower speeds aid in working on delicate or ornamental glass, higher productivity is attainable with faster speeds.

- Bevel Width:

An average quality machine should provide bevel widths ranging from 3 mm to 35 mm to cater to fine edging and bold chamfering.

- Glass Thickness Capacity:

Go for a machine with a minimum support thickness of 3 mm and a maximum of 19 mm, with scope for higher settings. This allows versatility for mirrors, architectural panels, and furniture glass.

- Number of Spindles:

Greater spindles, like on a 9-head or 11-head straight-line beveling machine, facilitate simultaneous grinding, beveling, and polishing of edges to guarantee perfect finishes.

- Motor Power:

The best machines have motors between 1.5 kW and 4 kW per spindle, offering stable, non-vibrating operation.

- Cooling System:

A dependable water circulation mechanism for cooling aids in heat dissipation, prolongs tool lifespan, and ensures precision.

- Control System:

Solutions for modern problems include CNC or digital PLC control panels for easier operation and enhanced precision.

Glass Beveling Machines’ Commercial Applications

Considering buying a glass beveling machine, you should pay attention to how multi-purpose these machines are across different branches, including graphic design and precision engineering.

- Architectural Glass

Glass for doors, partitions, curtain walls, and large glass panes requires machining. Our machines serve to bevel the glass, fulfilling supplementary aesthetic and structural needs for the home and buildings.

- Furniture Manufacturing

Beveling machines serve to elegantly round off glass edges on tabletops, glass doors of cabinets, and shelves with smooth, safe contours. It’s perfect for home and office premium furniture.

- Decorative and Commercial Mirrors

From vanity mirrors to large decorative installations, all precision edging is easily done with our bevelers that are ideal for mirror manufacturing.

- Solar Panel Production

Within the solar sector, careful edging, trimming, and beveling of the glass is done to maximize safety and performance. For the economical production of solar glass, there is a CNC glass beveling machine for sale, ideal for high-quantity, clean-edge solar glass manufacturing.

- Automotive Glass

In premium and custom vehicles, the use of beveled glass enhances the appealing contours to improve visibility, safety, and aesthetics.

Budget-Friendly: New and Used Beveling Machines

Our glass beveling machines come both used and new, since we know that financially tailored options are necessary.

New Machines:

• Latest technology

• Manufacturer warranty

• Optimized for energy efficiency

Where to Buy – Why Baineng?

We mix the best of both worlds at Baineng Machinery, making our products renowned for innovation and reliability.

- Certified ISO manufacturing

- Over 20 years of experience in glass machinery

- From portable to multi-head bevellers, we have almost every range of machines

- Custom design of machines is provided

- Competitive prices for local and international customers

- 24/7 User assistance

We don’t just sell machines, but rather establish long-lasting relationships with fabricators around the world.

Maintenance for Sustained Performance

Proper care extends the life of your glass edge working machine.

- Daily: Clean Water Tanks and Grinding Wheels

- Weekly: Provide Lubrication for Moving Components

- Monthly: Inspect Electrical Components and Water Seals

- Quarterly: Replace Polishing Pads That Show Signs of Wear and Evaluate the Condition of Motor Brushes

If assistance is needed, do not hesitate to contact our customer service team, who are always willing to help.

Conclusion

We are committed to empowering your operations, so if you are looking to purchase a glass workshop, BAINENG has the best glass beveling machine for sale, advanced in precision. Not only precision chamfering, or bulk edge polishing, but mirror beveling is also a feature of the machine.

TRENDING POSTS

- Glass Shape Edging Machine Product Solution 2025/05/14

HOT TOPIC

- architectural glass beveling machine

- automatic glass beveling machine

- Automotive Glass Beveling Machine

- cnc engraving machine manufacturer

- CNC glass beveling machine

- cnc glass edge polishing machine

- CNC glass grinding machine

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machining Center

- decorative glass beveling machine

- glass beveling and polishing machine

- glass beveling equipment

- glass beveling machine distributor

- glass beveling machine for sale

- glass beveling machine manufacturer

- glass beveling machine price

- glass beveling machine supplier

- glass door beveling machine

- glass edge beveling machine

- glass edge chamfering machine

- glass edge finishing machine

- glass edge grinding machine

- glass edge polishing machine

- glass edge processing machine

- glass edge shaping machine

- glass edge smoothing machine

- glass edge trimming machine

- glass furniture beveling machine

- glass panel beveling machine

- Glass Shape Edging Machine

- glass window beveling machine

- mirror beveling machine