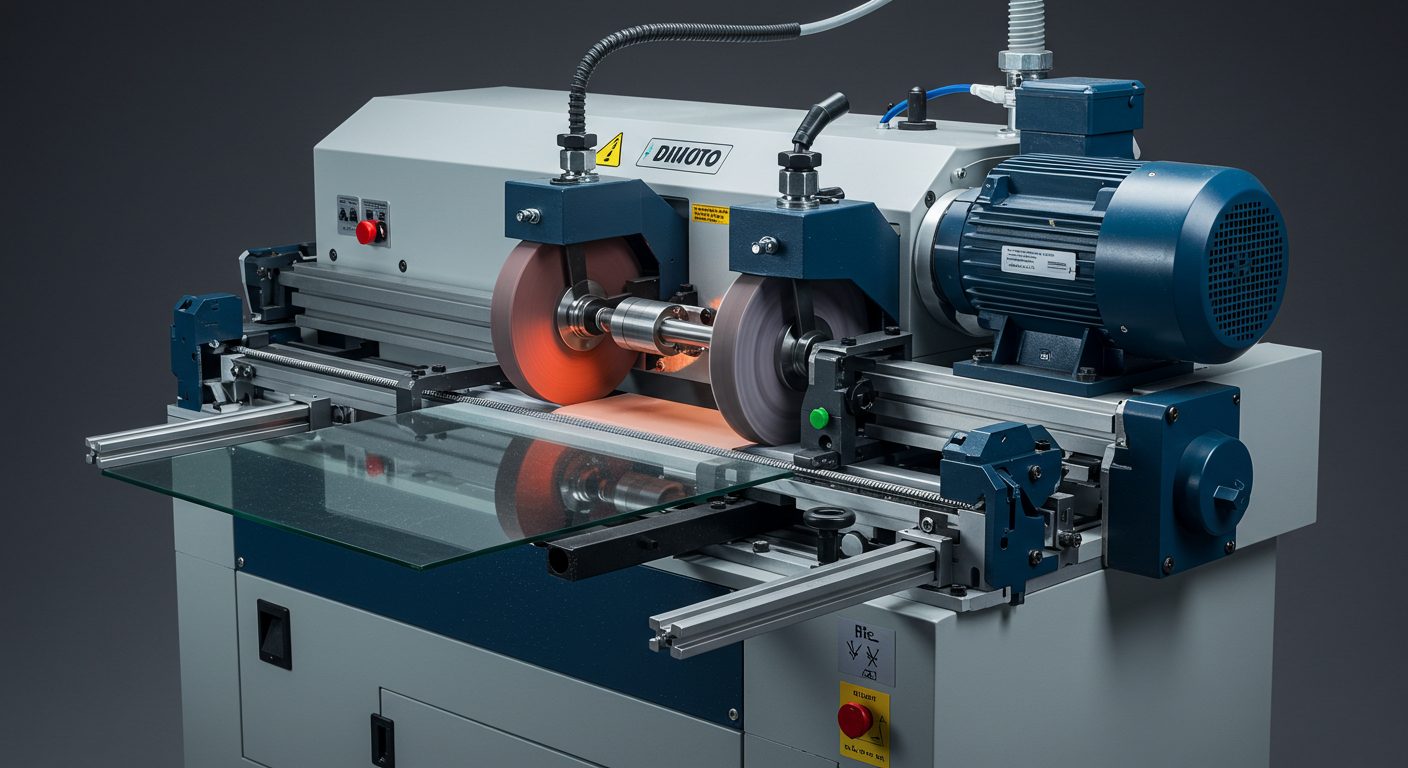

Glass Edge Grinding Machine Affordable for Your Business

2025/05/18 By admin

What is a Glass Edge Grinding Machine?

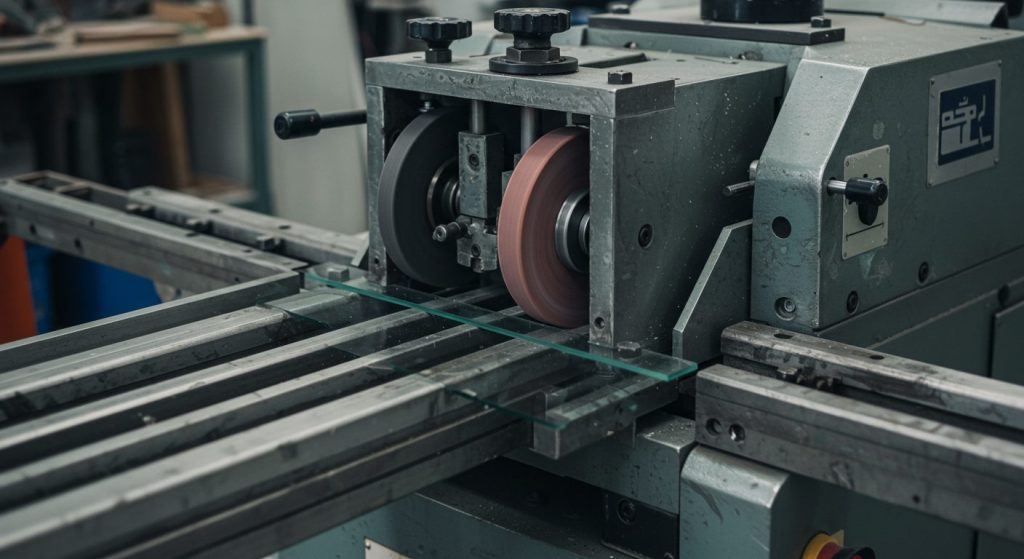

A glass edge grinding machine is custom-built equipment for cutting, beveling, polishing, or finishing work on the edges of glass sheets. These quality edging machines sharpen the glass edges while making glass products increasingly more refined and professional. If a company is engaged in a substantial amount of glass processing, such as construction, car assembly, and furniture making, the glass edging machine becomes highly essential.

Glass Edge Grinding Machines: All-Inclusive Types, Functions, and Uses Guide

Like in most industries, efficiency and accuracy are vital in glasswork. Consider a glass grinding machine to make sure all the edges of glass pieces are finely finished to achieve the beauty and usefulness of the final product. Such machines serve the needs of architectural glass and furniture glass, and also automotive glass.

Roles and Capabilities of Glass Edge Grinding Machines

The applications of glass edge grinding machine are extremely important, both for beauty and functionality. The following are some of the capabilities that these machines offer:

- Glass Edge Polishers

Except for its name, polishing is the final operation in the sequence of glass edge finishing. A glass edge polishing machine is equipped with polishing heads that are designed to obliterate every trace of roughness that was left behind by the preceding gloss grinding processes. This kind of polishing is unavoidable, especially in the manufacturing of high-quality types of furniture for pieces of glass or mirrors, where the edges have been ground.

- Glass Edge Grinding and Polishing

Some machines are constructed for the dual purpose of glass edge grinding and edge polishing. With the availability of such machines, time is saved because carrying out processes simultaneously is more beneficial in automated systems for glass edge finishing. These machines serve a multitude of uses, ranging from appliance glass processing to the grinding of automotive glass.

- Arising and Seaming

Glass pieces that are cut are left with sharp edges that are now dealt with using an arising machine that rounds off sharp edges. A glass seaming machine, as the name suggests, does rough edging to make the corners of the glass smooth transitions and contour.

- Beveling and Chamfering

Glass decorative artworks need tilted edges, which are achievable with a beveling machine. An object becomes less dangerous when edges are chamfered, making glass more user-friendly.

Uses of Glass Edge Grinding Machines

An assortment of types results from different branches using glass edge grinding machine. The most common are:

• Architectural Glass Grinding Machines: Used for oversized glass panes becoming windows, walls of edifices, and other landmark settings as building components.

• Furniture Glass Edging Machines: Usually involved in cleaning and polishing glass edges of display cases, tables, shelves, and other showroom furniture.

• Automotive Glass Grinding Machines: Fitted to the front and side doors of cars.

• Mirror Edge Grinding Machines: Developed for the edge and corner ring of mirror glass plates.

• Appliance Glass Grinding Machines: Used for glass parts of appliances to clean, polish, and soften edges, which are not sharp.

Choosing a Glass Edge Grinding Machine is a Delicate Decision

What are your benchmarks for selecting a glass grinding machine? We suggest optimizing the decision based on the following:

1. Classification of Glass: Different grades of glass require different machines. For instance, tempered glass and laminated glass have distinct processing requirements.

2. Capacity for Production: An automatic or CNC glass grinding machine may serve an educational purpose. Smaller portable ones are preferred by manually operated workshops.

3. Functional Characteristics: Will it perform beveling, polishing, self-grinding, or merely shape the glass? Some glass edge polishing machines do not have grinding or beveling capabilities, hence, functionality should be prioritized.

4. Funding Available and Space Available: The initial cost of smaller machines is usually low, but larger ones come at a higher cost; therefore, funding determines the type of equipment acquired, while the shop floor dictates the space requirements.

Maintenance Strategies for Glass Edge Grinding Machines

It focuses on optimizing the performance and service life of the equipment. To improve the performance of your machines, consider these suggestions:

• Maintenance includes cleaning the machine of grinding glass dust or any particulates.

• The grinding wheels should also be replaced depending on the wear radius of the wheel.

• Lubrication of the movable parts, which reduces wear of the machine, enhances machine longevity.

• Periodic calibrations of the machine are necessary to maintain accuracy.

What are the Baineng Services?

To maintain the starting performance and operational performance of the glass edge machines, Baineng customers are provided with comprehensive training materials designed around the customer that are equally comprehensive.

- Instructional Manual

The manual provides instructions structured as a checklist for each step, as well as installation, ensuring that no workflows are seamless. Precautionary measures are also delineated so that if adhered to, they will enable the operator to avoid problems when running and optimize efficiency.

- On-Site Training

Hands-on sessions in the organization’s field can be dealt with through on-site training with a specialized technician. Customized field service training is done at the customer’s site where the customer’s tools or equipment are located. Be informed that an extra service fee applies while conducting on-site training. You could also have an adequate management of operational risks with the glass grinding machine through the Baineng training services offered.

Conclusion

Smoothening and polishing the edges of glass products requires the glass grinding machine, which is a very important equipment within the glass processing industry. Machines offered to customers are of varied types, ranging from manual to CNC-controlled machines, depending on the specific needs and requirements of the buyers. The glass processing business becomes easier to manage with a better understanding of these machines and their uses. For further inquiries on glass edge grinding machine, visit the BAINENG website for an extensive collection and further assistance as well.

TRENDING POSTS

- Glass Shape Edging Machine Product Solution 2025/05/18

HOT TOPIC

- architectural glass beveling machine

- automatic glass beveling machine

- Automotive Glass Beveling Machine

- cnc engraving machine manufacturer

- CNC glass beveling machine

- cnc glass edge polishing machine

- CNC glass grinding machine

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machining Center

- decorative glass beveling machine

- glass beveling and polishing machine

- glass beveling equipment

- glass beveling machine distributor

- glass beveling machine for sale

- glass beveling machine manufacturer

- glass beveling machine price

- glass beveling machine supplier

- glass door beveling machine

- glass edge beveling machine

- glass edge chamfering machine

- glass edge finishing machine

- glass edge grinding machine

- glass edge polishing machine

- glass edge processing machine

- glass edge shaping machine

- glass edge smoothing machine

- glass edge trimming machine

- glass furniture beveling machine

- glass panel beveling machine

- Glass Shape Edging Machine

- glass window beveling machine

- mirror beveling machine