Looking for a Glass Edge Smoothing Machine? A Guide

2025/05/21 By admin

Explore Top-Rated Glass Edge Finishing Machines at Baineng

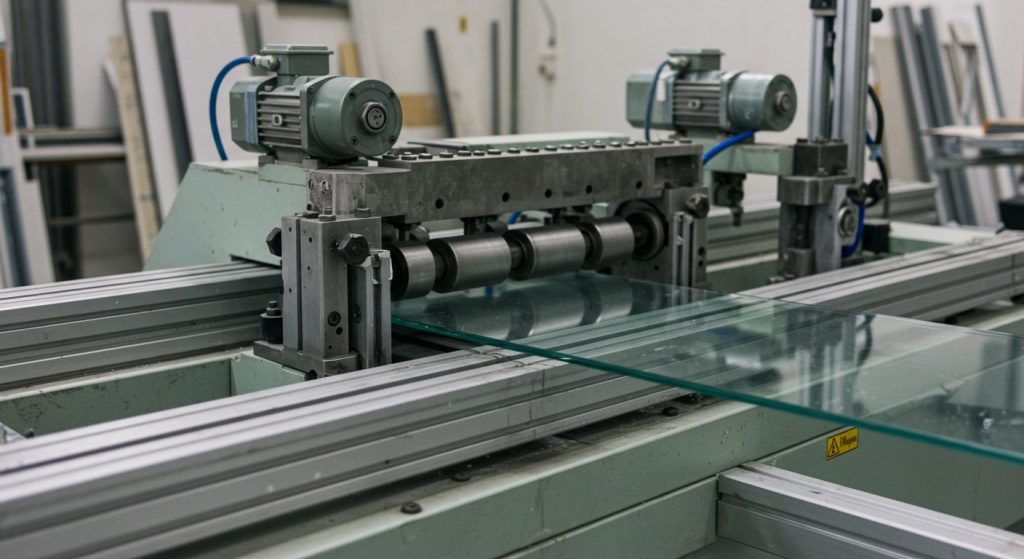

A glass edge smoothing machine is a unique piece of equipment that tasks with smoothing the edges of glass sheets. The process known as glass edge grinding helps in removing sharp edges and making the glass safer to handle as well as visually appealing. Depending on the model and its features, these machines can perform several operations like glass edge polishing, glass edge beveling, shaping, and grinding.

Different Types of Glass Edge Profiles

Depending on the application, different types of edge profiles are needed. Here are some of the widely used glass edge profiles that can be made using a glass edge smoothing machine.

• Flat Edge Grinding: The most common edge profile and the most simple of all.

• Pencil Edge Grinding: A soft and smooth, rounded edge is created at this edge.

• OG Edge Grinding: Widely used for furniture and ornament glass, this is a traditional decorative edge with a moderate radius curve.

• Bullnose Edge Grinding: This profile is greatly rounded and is ideal for where safety and visual appeal are needed

Glass Edge Smoothing Process

The process of smoothing glass edges has a few critical undertakings. This may vary based on the type of machinery employed. In broad strokes, the process includes;

Step 1: Edge Grinding

The most primitive stage of the process entails first grinding glass edges so that any roughness is removed and the surface is uniformly smooth. There are a myriad of grinders that can perform this: flat edge grinding machines, pencil edge grinding machines.

Step 2: Edge Polishing

Post grinding step, the glass edges are polished on a glass polishing machine to remove any additional imperfections and elevate the shine. This is the most important step, as it determines the shiny edge finish of glass

Step 3: Arising and Beveling

In scenarios with sharp edges, the glass undergoes a process to smooth sharp edges that could pose danger. Furthermore, glass edges can also be decorated with angles through a process known as beveling, combining aesthetics with functionality.

Step 4: Final Inspection

After these steps, the glass undergoes a checking process, inspecting the smoothness of the edges, safety, and readiness for final installation or further procedures.

Why Select a Machine for Smoothing Glass Edges

The glass edge smoothing machine is an important unit for virtually any glass workshop. Its technological features give several advantages that every glass manufacturer would want. These benefits include:

– Safety: The approach taken in glass edge polishing ensures that sharp, dangerous edges are completely eliminated.

– Functional Value: The finishing of the glass significantly increases its value and makes it look more professional.

– Productivity: Performs cutting of the glass edges with great speed, especially for the automatic glass edge smoothing machines.

– Flexibility: These machines can treat different categories of glass, like automotive glass, furniture glass, and architectural glass, even tempered and laminated glass.

Specifications That Come With a Glass Edge Smoothing Machine

When looking for a glass edge smoothing machine, there are a few standards that you want to follow to check if the machine meets your specifications:

Self-Sufficient Transactions

An example would be the CNC glass edge polishing machines with automation features. With the automated systems, it is possible to achieve higher standards of consistency, accuracy, and productivity, all at the same time, elevating the results of productivity for bulk works.

Speed

Fast glass edge smoothing machines are a requirement in large-volume production settings. Faster machines can handle more glass panels in less time, making them suited for industries with quick turnaround requirements.

Size

A small glass edge smoothing machine might be suitable for operations on a smaller scale. These machines are compact and fairly powerful, making them ideal for workshops with space constraints.

Common Applications for Glass Edge Smoothing Machines

Automotive Glass Processing

In the automotive sector, automotive glass edge smoothing machines are utilized to make sure windows and mirrors have polished edges that are safe and visually appealing.

Furniture Glass Processing

For furniture glass, which includes table tops, shelves, and cabinet doors, a furniture glass edge smoothing machine ensures that the edges are smooth and free from any sharpness for safety and beauty.

Architectural Glass Processing

The architectural glass utilized in windows, facades, and doors needs precise edge smoothing for both functional and aesthetic reasons. A glass edge finishing machine meant for architectural glass provides smooth edges to items of high standards.

How to Smooth Glass Edges With a Machine?

Smoothing glass edges is not a complicated task, but it has to be accomplished with the right technique and equipment. Here’s a step-by-step method on how to do it:

Choose the right machine: A glass edge grinding and polishing machine must be chosen according to the type of glass and the final result to be achieved.

Set up the machine: Put on the correct abrasive wheels or polishing pads that suit the task to be carried out

Work on the piece of glass: Place the glass in the machine and proceed to perform grinding, polishing, and possibly beveling or shaping.

Check the edges: Visually examine the glass edges and assess them for smoothness and grade of finish

Conclusion

Acquiring a glass edge smoothing machine will most certainly increase the value and quality of your glass products. These machines are beneficial in achieving professionally smooth, polished edges, whether in automotive, furniture, or architectural glass processing. There is a model for every need, including automatic, manual, and portable machines. It is best to look for automation, speed, and portability when selecting a machine that best suits your company. For further details on the best glass machines, please visit Baineng. We offer a variety of machines tailored to the needs of different sectors while providing efficiency, precision, and safe glass edge finishing for all processes.

TRENDING POSTS

- Glass Shape Edging Machine Product Solution 2025/05/21

HOT TOPIC

- architectural glass beveling machine

- automatic glass beveling machine

- Automotive Glass Beveling Machine

- cnc engraving machine manufacturer

- CNC glass beveling machine

- cnc glass edge polishing machine

- CNC glass grinding machine

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machining Center

- decorative glass beveling machine

- glass beveling and polishing machine

- glass beveling equipment

- glass beveling machine distributor

- glass beveling machine for sale

- glass beveling machine manufacturer

- glass beveling machine price

- glass beveling machine supplier

- glass door beveling machine

- glass edge beveling machine

- glass edge chamfering machine

- glass edge finishing machine

- glass edge grinding machine

- glass edge polishing machine

- glass edge processing machine

- glass edge shaping machine

- glass edge smoothing machine

- glass edge trimming machine

- glass furniture beveling machine

- glass panel beveling machine

- Glass Shape Edging Machine

- glass window beveling machine

- mirror beveling machine