Mirror Beveling Machine: Your Guide to Perfect Glass Edges

2025/05/17 By admin

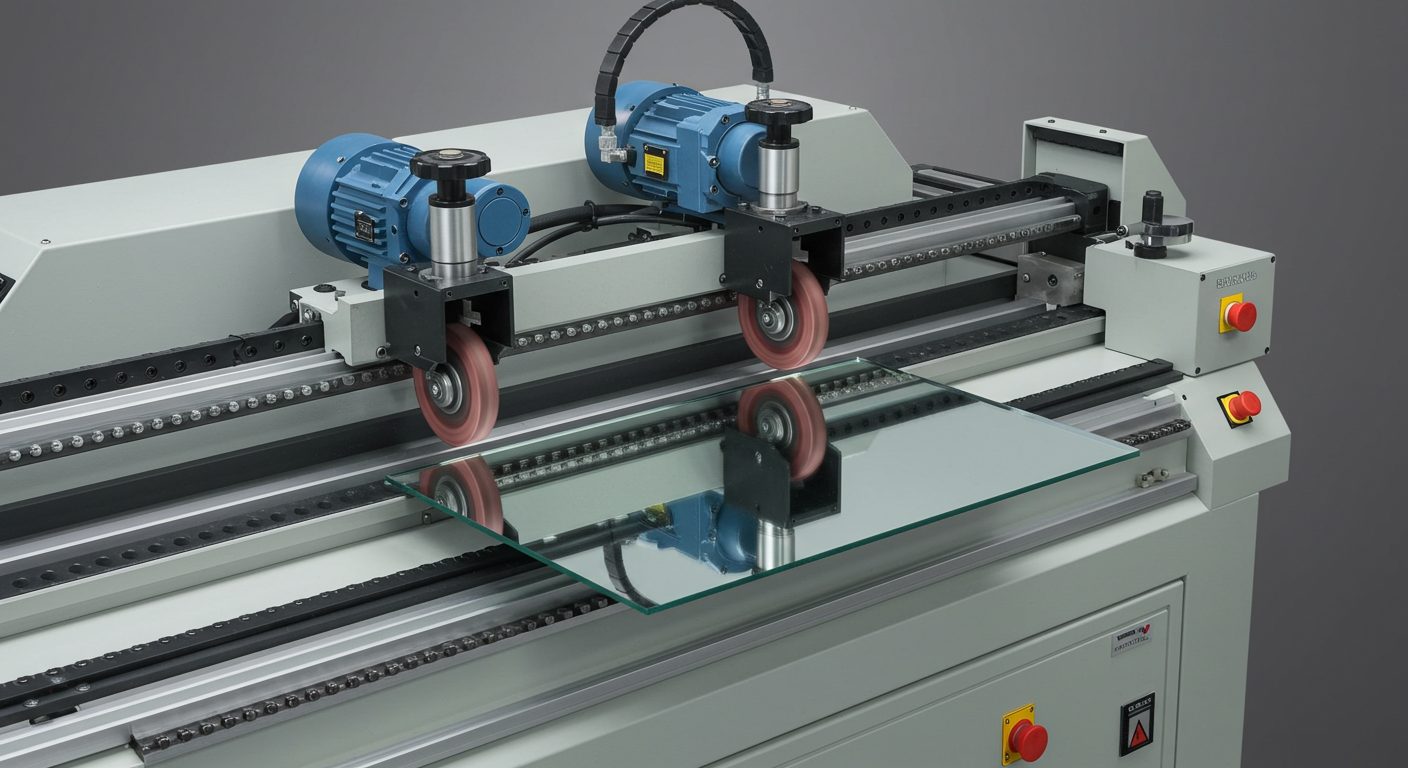

What is a Mirror Beveling Machine?

- A mirror beveling machine is a specialized glass mirror edge processing machine. The beveling procedure entails putting a chamfer 20 to 45-degree angle on the edges of glass, which involves both grinding and polishing. Such procedures not only enhance the beauty of the mirrors, but they also help in making mirrors safer during handling by removing sharp edges.

- Different types of these machines exist, including CNC beveling machines, automatic beveling machines, double-edging beveling machines, and so forth. Each of these comes with different features and advantages aimed at distinct production requirements.

Introduction to Mirror Beveling Machine

Achieving refinement in crafting glass furniture requires utmost precision. The finesse steps taken with glass edges must combine strength with beauty, and the mirror beveling machine makes this possible. Whether you are in the furniture, architectural design sector, or even in mirror making, the right beveling tools can give your products unprecedented quality.

The Functions of the Glass Beveling Device

- Mirror Beveling and Its Features

The ability of a glass beveling machine to make as important as precision in the beveled edges. With a combination of grinding wheels and polishing pads, the last glass edges were achieved smoothly and flawlessly. With their automatic functions, these machines are best suited for automatic precision CNC work.

- Adjustable and Automatic Features

In many newer models of automatic mirror machines, the operator has the right to set the speed, pressure, and beveling angles and adjust them to warmer scenes. This lets the work range from small decorative mirrors to large architectural ones. Such tenability of the settings guarantees that the machine produces the same results all the time.

- Pattern Recognition and Volume Content

The durability and performance of a mirror beveling him are seen from the way he has been constructed. It also takes into account their work life, these high-quality machines that are made to be visually appealing and durable, all at the same so the brittle nature of glass does not weaken their grinding and polishing production capabilities.

Uses of Mirror Beveling Machines

- Furniture Mirror Beveling

The furniture beveling machines are used to put a bevel on mirrors used in furniture, which includes vanity mirrors, tabletops, and cabinet doors. They polish the edges to enhance the overall standards of the furniture pieces.

- Decorative Glass Edging

These machines are adjustable to produce smooth and decorative cuts to mirrors, picture frames, and glass art pieces. These beveled edges give character and sophistication to almost any set in the house.

- Architectural Glass Processing

In architectural design, beveling is used in large-scale projects to provide sleek and refined edges to glass. Designing with an architectural mirror

machine allows them to fit glass panels with beveled edges into contemporary buildings and structures. It is versatile and precise for architectural glass processing.

Purchasing Guidelines for Mirror Beveling Machines

When purchasing beveling machines, one of the first things to pay attention to is the specific needs of your business. Choosing the right machine is vital, regardless of whether your specialty is furniture, decorative mirrors, or architectural glass, as it determines production efficiency and product quality.

- Evaluate Your Requirements

The first step is to define the exact tasks that you will be executing with the machine. Will you be needing a CNC mirror beveling machine for detailed work, or can you go with a basic straight line beveling machine? Take into account the size of your business and the types of glass that will be processed.

- Look for Quality

Purchase a mirror beveling machine from suppliers with solid reputations for producing high-quality machines that are built for enduring use. Such machines that have well-established brands like Baineng and are constructed of strong materials tend to be more reliable and last longer.

- Think about Automation

Get these machines if productivity is what you are after. Automatic beveling machines give better results because of consistency and less manual handwork that is done on these machines. These features make automatic beveling machines desirable in a business with large production outputs.

- Assess the Costs

While pricing significantly matters, it is vital to keep in mind that purchasing a beveling machine is an investment. Evaluate the overall savings from lower-maintenance work on the machine in the long run. There are new and used beveling machines available, which allow for more flexibility with pricing. To learn more about the available beveling machines that Baineng sells, feel free to reach out.

Maintenance of Mirror Beveling Machines

Preserving the glass beveling machine requires proper upkeep. Maintaining the machine’s moving parts and cleaning the machine after every use is vital for extending its lifespan. Machine users must also check for worn-out pads and wheels, which is integral to the machine’s overall functionality.

- Operator Safety

A beveling machine, like any other machinery, requires that users prioritize safety at all times. In machine operation, all set guidelines must be observed to ensure proper functions and accident-free operations. Operators must possess adequate knowledge of the beveling machine’s control and safety functions, which are necessary for effective usage.

Where to Buy a Mirror Beveling Machine?

If you are searching for a beveling machine, Baineng has an extensive collection of glass beveling machines suitable for all industries. If you want a compact and portable machine or an industrial-grade beveling machine, Baineng has cutting-edge and dependable options.

Conclusion

Purchasing a mirror beveling machine is a worthwhile investment for companies dealing in glass and mirrors. Whether it is furniture, decor, or architecture, glass beveling enhances safety, style, and sophistication. Understanding the different types of beveling machines and selecting the right one specific to your production requirements will allow you to produce high-quality standard products. Visit BAINENG.

TRENDING POSTS

- Glass Shape Edging Machine Product Solution 2025/05/17

HOT TOPIC

- architectural glass beveling machine

- automatic glass beveling machine

- Automotive Glass Beveling Machine

- cnc engraving machine manufacturer

- CNC glass beveling machine

- cnc glass edge polishing machine

- CNC glass grinding machine

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machining Center

- decorative glass beveling machine

- glass beveling and polishing machine

- glass beveling equipment

- glass beveling machine distributor

- glass beveling machine for sale

- glass beveling machine manufacturer

- glass beveling machine price

- glass beveling machine supplier

- glass door beveling machine

- glass edge beveling machine

- glass edge chamfering machine

- glass edge finishing machine

- glass edge grinding machine

- glass edge polishing machine

- glass edge processing machine

- glass edge shaping machine

- glass edge smoothing machine

- glass edge trimming machine

- glass furniture beveling machine

- glass panel beveling machine

- Glass Shape Edging Machine

- glass window beveling machine

- mirror beveling machine