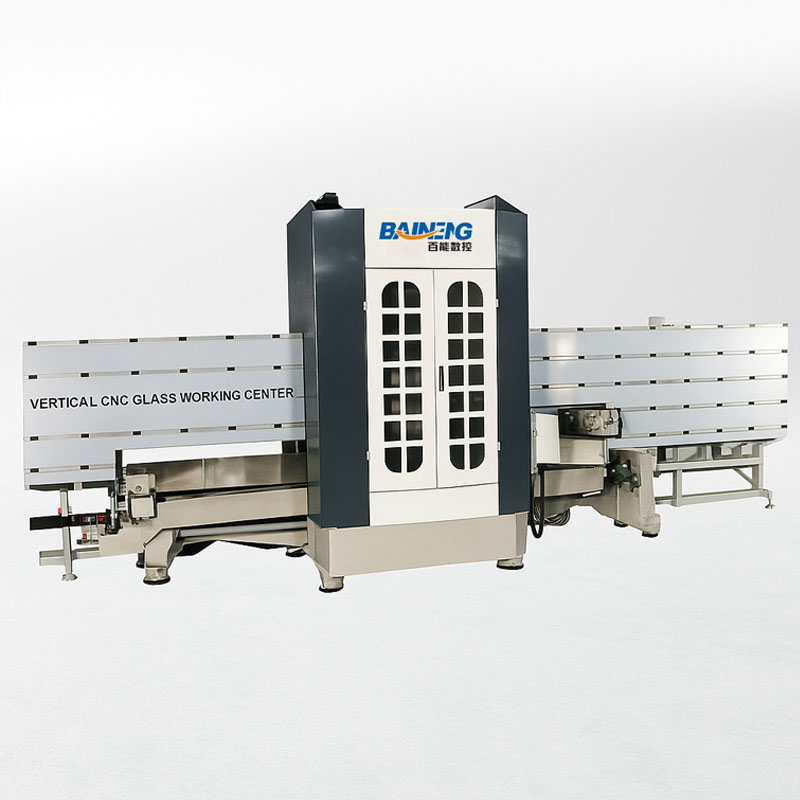

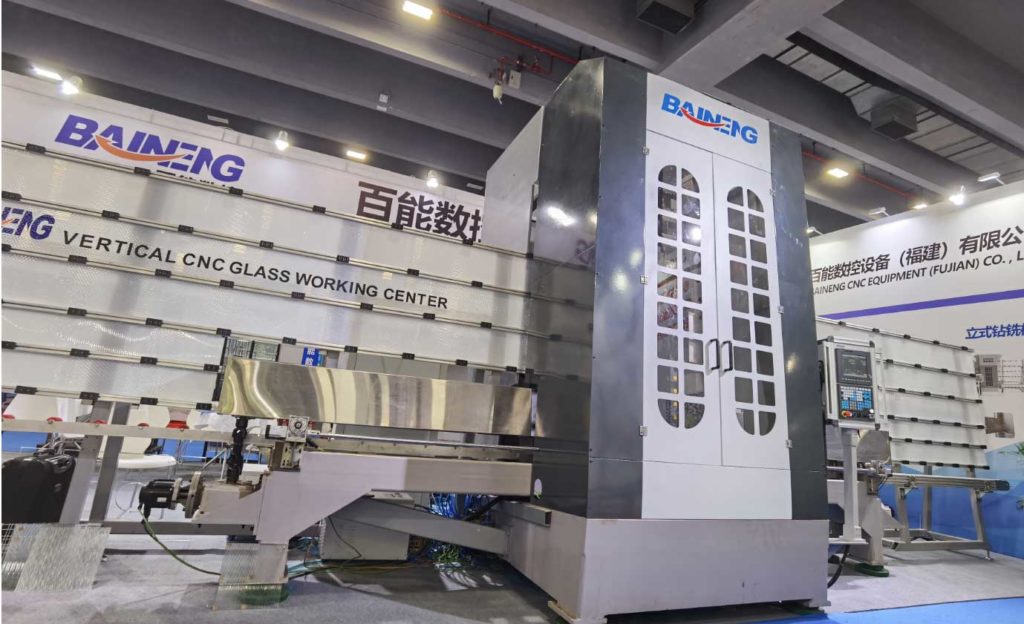

CNC Glass Vertical Working Center

A CNC Glass Vertical Working Center is a highly advanced, precision-driven machine designed for the processing of glass materials in various industrial and commercial applications. It is equipped with a computer numerical control (CNC) system that automates the glass cutting, grinding, drilling, and shaping processes, ensuring high efficiency, accuracy, and versatility. Typically used in industries like construction, automotive, furniture, and more, the CNC Glass Vertical Working Center allows for the complex handling of glass with minimal human intervention while maintaining precision and repeatability.

Key Features

-

Multi-Functionality: Capable of performing a wide range of operations, including cutting, grinding, beveling, drilling, edge polishing, and engraving. This makes it ideal for creating customized glass products with varying degrees of complexity.

-

Automatic Loading/Unloading: The system is often equipped with an automatic glass loading and unloading mechanism, allowing for continuous operation without the need for manual handling, increasing productivity and safety.

-

High Precision and Speed: CNC Glass Vertical Working Centers offer superior precision in processing, which is essential for high-quality glass products. This precision is maintained even during complex operations like beveling or drilling multiple holes.

-

Adaptability to Different Glass Types: These machines can handle various glass types such as tempered glass, laminated glass, frosted glass, and more, offering versatility across industries.

-

Advanced Safety Features: Safety is a priority, with built-in systems to protect the operator, such as emergency stop functions, safety barriers, and automatic glass handling.

Technical Specifications

- Maximum Processing Size: 3000mm x 1500mm

- Processing Thickness: 3mm – 25mm

- Spindle Power: 9kW

- Processing Speed: 0 – 12 meters/minute

- Positioning Accuracy: ±0.02mm

- Control System: CNC numerical control system

- Cooling System: Water cooling

A CNC Glass Vertical Working Center is a specialized machine tool that is used for shaping, cutting, drilling, and finishing glass products in a vertical orientation. The machine operates based on CNC programming, where operators input specific design parameters, and the machine automatically carries out the required tasks on the glass. This highly automated process significantly reduces the risk of human error and improves the overall quality and consistency of the glass products being produced.

These working centers can handle a wide range of glass thicknesses and types, from simple cutting to intricate processes such as edge polishing, glass beveling, and hole drilling. The vertical design maximizes workspace efficiency and accommodates larger glass sheets or panels, ensuring smoother operations and reducing the need for manual handling.

Advantages of CNC Glass Vertical Working Center

-

Increased Productivity: By automating the entire glass processing operation, the CNC Glass Vertical Working Center greatly reduces the amount of manual labor required, boosting productivity and throughput.

-

High Precision and Consistency: CNC technology allows for highly accurate and repeatable results, ensuring that each piece of glass meets strict quality standards with minimal deviation.

-

Customization and Flexibility: This system is capable of handling customized glass shapes and designs, providing flexibility in producing unique glass products tailored to specific customer requirements.

-

Reduced Labor Costs: The automation and ease of operation reduce the need for highly skilled labor and minimize human error, lowering the overall operational cost.

-

Enhanced Safety: The inclusion of automatic loading and unloading systems, along with safety mechanisms, reduces the risk of accidents and injuries, creating a safer working environment.

Why Choose CNC Glass Vertical Working Center?

If your business demands the highest quality of glass products, a CNC Glass Vertical Working Center is an ideal choice. Its precision ensures that even complex shapes and intricate designs are produced without compromising on quality. The automation of processes means you can complete more projects in less time. From large-scale glass cutting to intricate custom designs, the system optimizes the entire workflow.

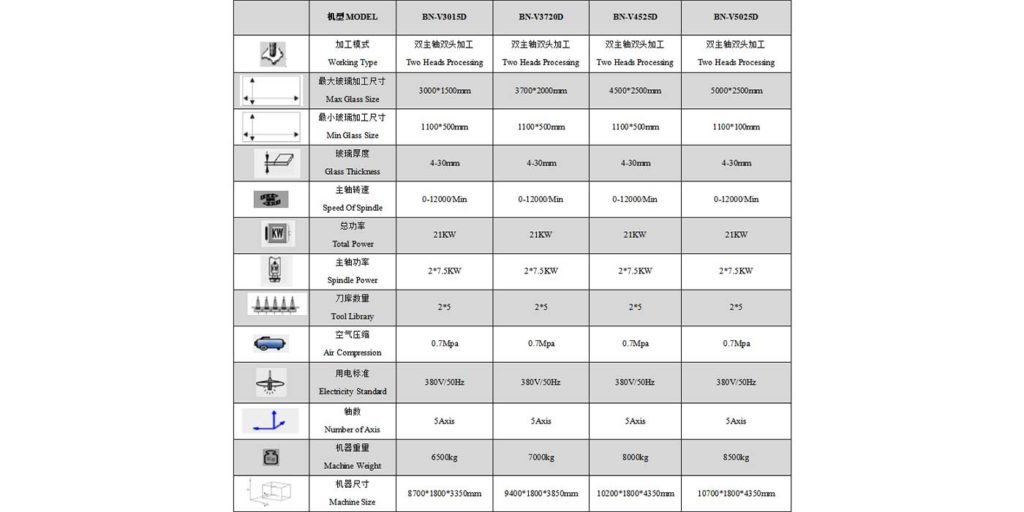

Technical Parameter

Parts Advantage

Parts Advantage

| Description | Brand | Made in |

| Linear Guide | Hiwin | Taiwan |

| Ball Screw | HIWIN/TPI | Taiwan |

| Servo Motor | Mitsubishi | Japan |

| Bearing | NSK | Japan |

| Control System | Syntec | Taiwan |

| Control Electrical | SCHNEIDER | France |

| Image Converter Software | BAINENG | China |

| Description | Quantity | Remark |

| Gloves | 1pair | / |

| Adjustable cushion | 4pcs | / |

| X axis synchronous belt | 1pcs | / |

| Toolbox | 1box | / |

| Adjustable wrench | 1pcs | 250*30(mm) |

| Allen wrench | 9pcs | S1.5 S2.0 S3.0 S4.0 S5.0 S6.0 S8.0 S10.0 S.12 |

| Inner Allen screw | some pieces | M6*10,M6*20 |

| Thread seal tap | 1pcs | / |

| 3functions in one tool | 3pcs | / |