CNC Vertical Glass Drilling and Milling Machine

Combining advanced technology with precision engineering, the baineng CNC vertical glass drilling and milling machine is designed to perform complex drilling and milling tasks with exceptional accuracy and efficiency. This high-performance machine delivers premium processing quality, enabling users to achieve professional results with a minimal investment in CNC equipment.

Key Features

-

CNC Control System: The heart of the machine, the CNC control system, ensures precise and automated drilling and milling operations. The control software allows users to input specific parameters for hole locations, shapes, sizes, and edge designs, ensuring accuracy and consistency.

-

Vertical Orientation: The vertical design provides better access to larger glass panels and optimizes floor space, making it easier to handle larger glass sheets. The vertical setup also reduces the risk of glass damage during the processing.

-

Multiple Operations: The machine is capable of performing multiple tasks such as drilling holes, milling edges, slotting, and chamfering, all in one operation. This eliminates the need for multiple machines and streamlines the production process.

-

High-Speed Drilling and Milling: Equipped with powerful spindles and high-speed motors, the machine ensures fast drilling and milling operations, improving productivity and reducing production time.

-

Precision and Accuracy: CNC technology ensures that each hole, slot, or cut is made with high precision, down to millimeters or even fractions of a millimeter. This is critical for applications requiring detailed design work or tight tolerances.

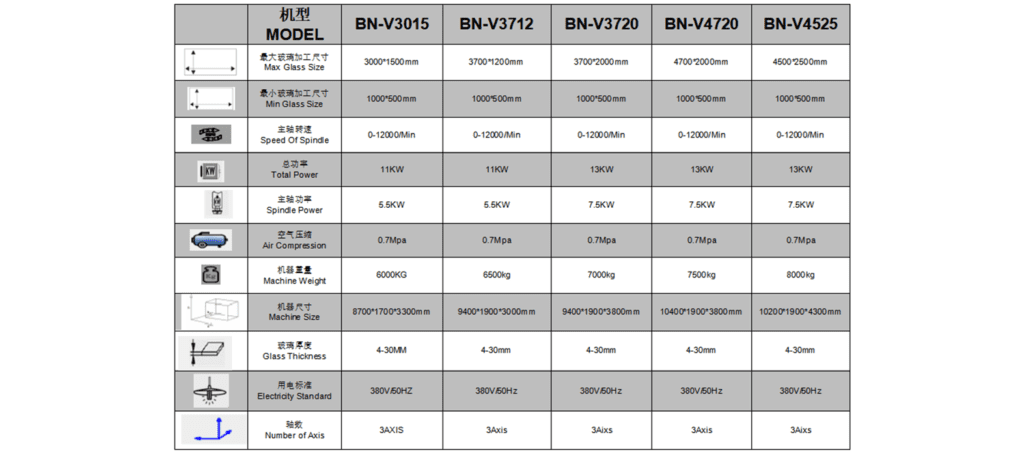

Technical Specifications

- Maximum Processing Size: 3000mm x 1500mm

- Processing Thickness: 3mm – 25mm

- Spindle Power: 7.5kW

- Processing Speed: 0 – 12 meters/minute

- Positioning Accuracy: ±0.02mm

- Control System: CNC numerical control system

- Cooling System: Water cooling

A CNC Vertical Glass Drilling and Milling Machine is a versatile, automated machine used for drilling holes, shaping, cutting, and milling glass in a vertical orientation. It uses a CNC control system to accurately execute operations like drilling holes for hardware installation, milling edges, or creating custom profiles and slots in glass panels. The vertical setup helps maximize workspace efficiency, particularly when working with large sheets of glass, and allows for intricate design features and high-quality finishes.

Advantages of CNC Vertical Glass Drilling and Milling Machine

-

Enhanced Precision and Consistency: The use of CNC technology ensures high levels of precision for drilling and milling tasks, resulting in consistently accurate glass products. This is essential for industries where quality and uniformity are paramount, such as automotive and architecture.

-

Increased Productivity: The automation of the drilling and milling processes reduces the need for manual labor, speeding up production times. The high-speed motors and the ability to perform multiple tasks in one cycle further enhance throughput.

-

Flexibility for Custom Designs: The CNC control system offers flexibility for custom designs. It allows for the processing of complex shapes, precise hole placements, and edge milling patterns, making it ideal for both mass production and custom projects.

-

Cost-Effective: Although the initial investment in a CNC Vertical Glass Drilling and Milling Machine can be high, the efficiency, precision, and reduction in labor costs lead to significant savings over time. The machine’s versatility also eliminates the need for multiple machines, further cutting costs.

Why Choose CNC Vertical Glass Drilling and Milling Machine?

If your business requires highly accurate drilling or milling of glass, the CNC Vertical Glass Drilling and Milling Machine ensures that each hole or cut is made to precise specifications. Whether it’s for decorative glass, architectural applications, or automotive components, the machine’s precision guarantees flawless results. The ability to perform multiple operations in one cycle, coupled with high-speed drilling and milling, allows businesses to significantly improve their production efficiency. This is especially beneficial for high-volume production, where fast turnaround times are essential.

Technical Parameter

| Description | Brand | Made in |

| Linear Guide | Hiwin | Taiwan |

| Ball Screw | HIWIN/TPI | Taiwan |

| Servo Motor | Mitsubishi/Syntec | Japan/Taiwan |

| Bearing | NSK | Japan |

| Sliding Block | Hiwin | Taiwan |

| Control System | Syntec | Taiwan |

| Control Electrical | SCHNEIDER | France |

| Image Converter Software | BAINENG | China |

| Spindle | Baineng | China |

| Synchronous Belt | / | China |

| Air Cylinder | Airtac | Taiwan |

| Synchronous Wheel | / | China |

| Water Pump | / | China |

| Steel Plate | Baosteel | China |

| Protection Cover | / | China |

| Description | Quantity | Remark |

| Gloves | 1pair | / |

| Adjustable cushion | 4pcs | / |

| X axis synchronous belt | 1pcs | / |

| Toolbox | 1box | / |

| Adjustable wrench | 1pcs | 250*30(mm) |

| Allen wrench | 9pcs | S1.5 S2.0 S3.0 S4.0 S5.0 S6.0 S8.0 S10.0 S.12 |

| Inner Allen screw | Some pcs | M6*10,M6*20 |

| Allen Nut | Some pcs | M10*20,M6*10,M6… |

| Thread seal tape | 1pcs | / |

| Water Pump | 1set | / |

| Transformer | 1set | / |

| Spindle water cooled machine | 1set | / |

| 3functions in one tool | 3pcs | Including milling, drilling, chamfering |