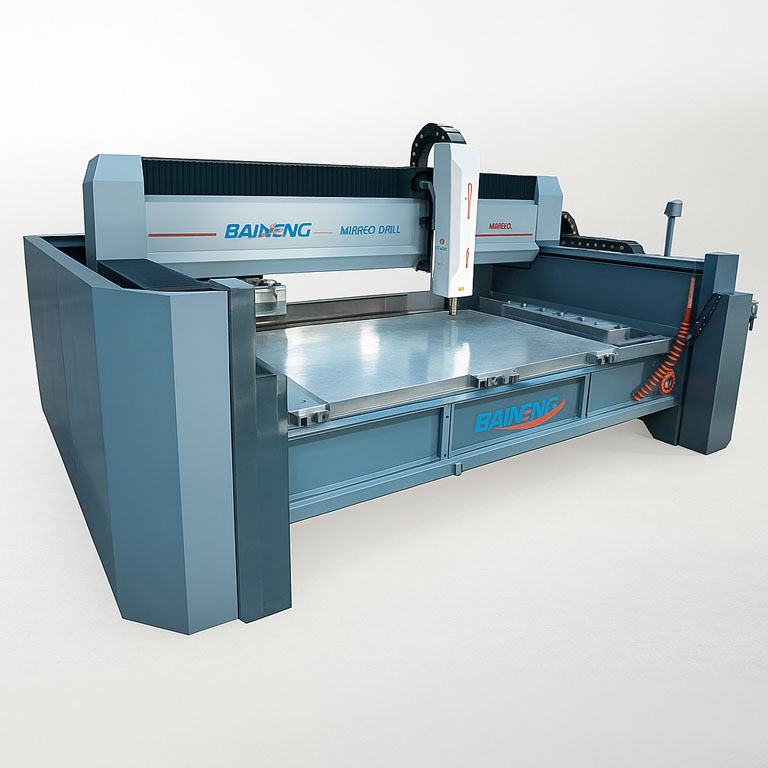

Glass Fabrication Machine

A Glass Fabrication Machine is an advanced industrial tool used for shaping, cutting, edging, drilling, and finishing glass materials. These machines are essential in a wide variety of industries, including architecture, automotive, interior design, and furniture production. Glass fabrication involves creating specific shapes, sizes, and finishes for glass components, and these machines automate the process to achieve high precision, increased efficiency, and reduced labor costs.

Key Features

-

CNC Control System: The integration of CNC technology allows the glass fabrication machine to operate with high precision. Operators can input design files, and the machine will automatically execute the cutting, shaping, and finishing tasks with minimal human intervention, ensuring consistency and accuracy.

-

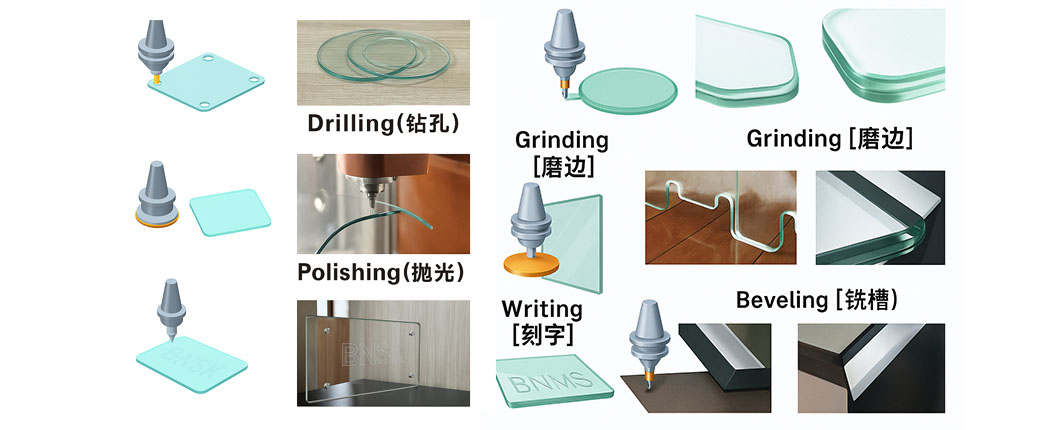

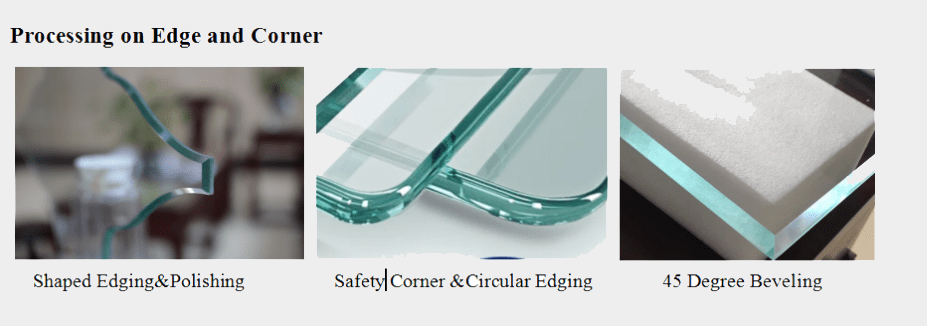

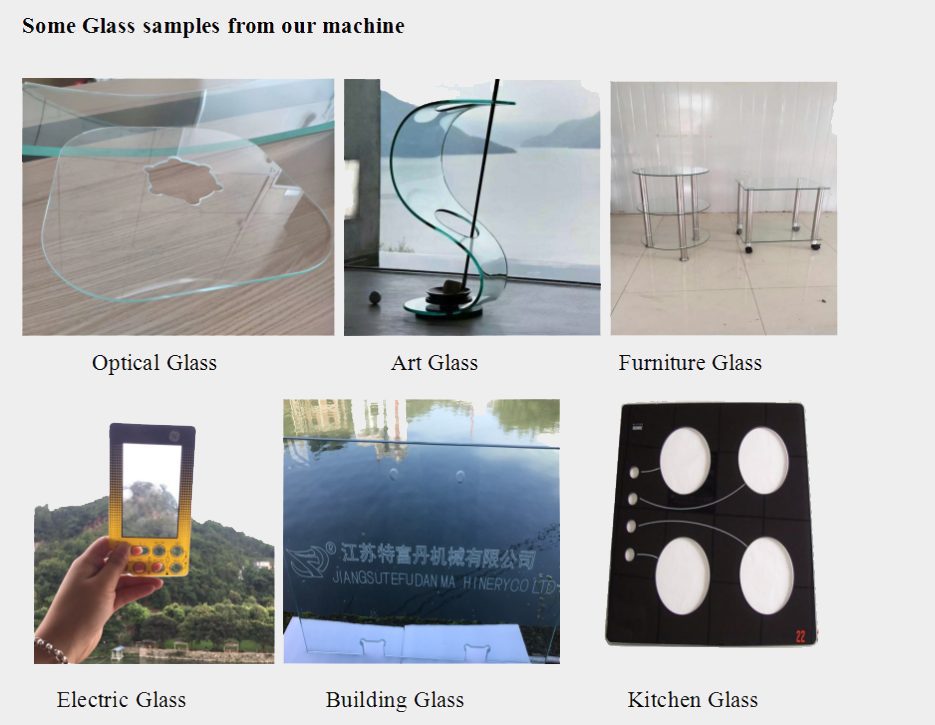

Versatility in Operations: These machines can perform various tasks such as cutting, edging, grinding, polishing, drilling, and even engraving.

-

High-Speed Processing: Modern glass fabrication machines are designed for fast and efficient processing, which is especially beneficial for high-volume production environments.

-

Precision Cutting and Shaping: The accuracy of CNC-controlled cutting and shaping is a significant advantage. Glass fabrication machines can produce pieces with very tight tolerances, which is crucial for industries requiring precise measurements, such as architectural glass, automotive, or glassware manufacturing.

Technical Specifications

- Maximum Processing Size: 3000mm x 1500mm

- Processing Thickness: 3mm – 25mm

- Spindle Power: 9kW

- Processing Speed: 0 – 12 meters/minute

- Positioning Accuracy: ±0.02mm

- Control System: CNC numerical control system

- Cooling System: Water cooling

A Glass Fabrication Machine is a piece of machinery designed to process raw or semi-finished glass materials. These machines are used for cutting, grinding, polishing, drilling, beveling, and shaping glass into various products or components. They are equipped with specialized tools such as saws, grinders, and drills, all of which are controlled by automated systems, including CNC (Computer Numerical Control), to ensure high precision and repeatability.

Advantages of Glass Fabrication Machine

-

Increased Efficiency and Productivity: The automation and precision offered by glass fabrication machines result in faster processing times and higher throughput.

-

High Precision and Accuracy: Glass fabrication machines, particularly those with CNC controls, are capable of producing glass components to extremely tight tolerances, ensuring consistent quality.

-

Flexibility and Versatility: These machines can be used for a wide range of glass types and thicknesses, making them versatile in different manufacturing environments.

-

Cost-Effectiveness: Although the initial investment in a glass fabrication machine may be high, the long-term benefits include reduced labor costs, minimal waste, and increased production speeds.

-

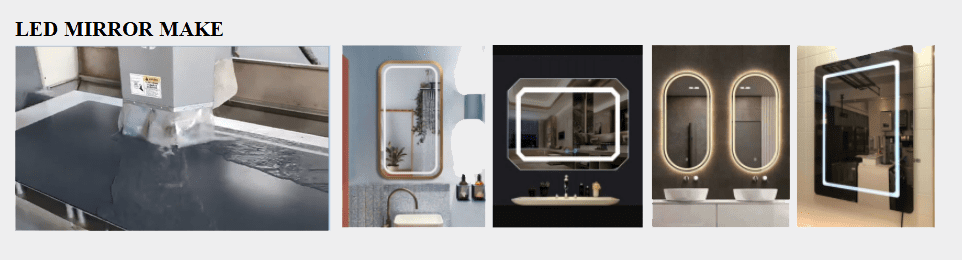

Customization and Design Flexibility: Glass fabrication machines allow for customization of glass shapes, sizes, and finishes, making them ideal for producing unique or specialized products. The flexibility to create custom designs is especially valuable in industries like interior design, custom glassware, and architectural glass.

-

Improved Safety: With the automation of glass cutting, grinding, and polishing, glass fabrication machines reduce the risk of injuries associated with manual glass processing.

Why Choose a Glass Fabrication Machine?

If your business requires consistent, high-quality glass components, a glass fabrication machine is the right investment. These machines deliver precise and polished results, ensuring your products meet the highest standards. With the ability to automate and speed up processes, glass fabrication machines help businesses increase their production capacity. Whether it's for large-scale manufacturing or custom one-off designs, these machines offer the flexibility needed to meet growing demands.

Technical Parameter

| MODEL NO. | BN-T2412 | BN-T2416 | BN-T2620 | BN-T3016 | BN-T3020 | BN-T3720 |

| Stroke of X.Y.Z-Axis | 2400*1200*200mm | 2500*1700*200mm | 2600*2000*200mm | 3000*1600*200mm | 3000*2000*200mm | 3700*2000*200mm |

| Speed of X.Y-Axis | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) |

| Speed of Z-Axis | 15(m/min) | 15(m/min) | 15(m/min) | 15(m/min) | 15(m/min) | 15(m/min) |

| Max Size of Glass | 2400*1200(mm) | 2400*1600mm | 2600*2000(mm) | 3000*1600(mm) | 3000*2000(mm) | 3700*2000(mm) |

| Min Size of Glass | 200*200 (mm) | 200*100 (mm) | 200*200 (mm) | 200*200 (mm) | 200*200 (mm) | 200*200(mm) |

| Glass Thickness | 1-40 (mm) | 1-40 (mm) | 1-40 (mm) | 1-40 (mm) | 1-40 (mm) | 1-40(mm) |

| Tool Library(PCS) | 1*4 | 2*4 | 2*5 | 2*4 | 2*5 | 2*5 |

| Spindle Speed | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) |

| Spindle Power | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) |

| Total Power of Machine | 17-21kw | 17-21kw | 17-21kw | 17-21kw | 17-21kw | 17-21kw |

| Voltage | 380V | 380V | 380V | 380V | 380V | 380V |

| Internal Water Consumption | 3 L/min | 3 L/min | 3 L/min | 3 L/min | 3 L/min | 3 L/min |

| External Water Consumption | 100 L/min | 100 L/min | 100 L/min | 100 L/min | 100 L/min | 100 L/min |

| 空气压缩Air Compression | 0.75MPA | 0.75MPA | 0.75MPA | 0.75MPA | 0.75MPA | 0.75MPA |

| Weight | 4800kg | 5000kg | 6000kg | 6000kg | 6500kg | 8100kg |

| Shipment Size | 5000*2300*2300(mm) | 4700*2300*2300mm | 5200*2300*2300(mm) | 5600*2300*2300(mm) | 5600*2300*2300(mm) | 6300*2300*2300(mm) |