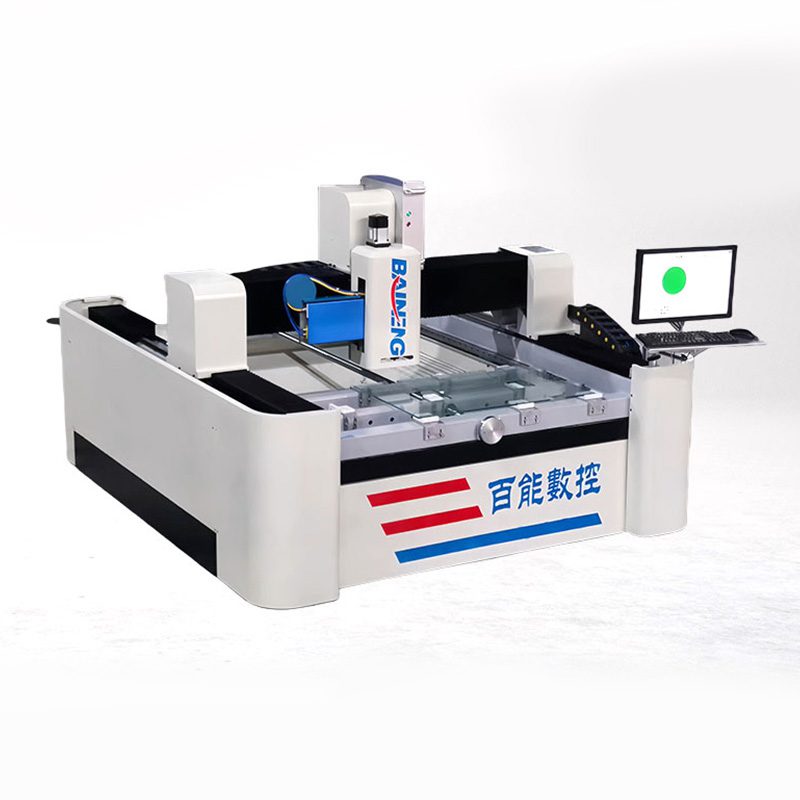

Glass Laser Multi-functional Machine

This machine is a laser engraving system specifically built for glass and mirror applications, with added flexibility to work on metals and other flat surfaces. It uses precise laser dotting technology to create clean, detailed patterns or designs. Controlled by intelligent software, the machine ensures consistent results and a smooth, automated workflow.

Key Features

-

Built-in Templates & Intelligent Software – Simple operation with automatic path generation.

-

Durable Build – Engineered for long-term, continuous use in factory environments.

-

Compact Design – Saves space and fits seamlessly into modern production lines.

-

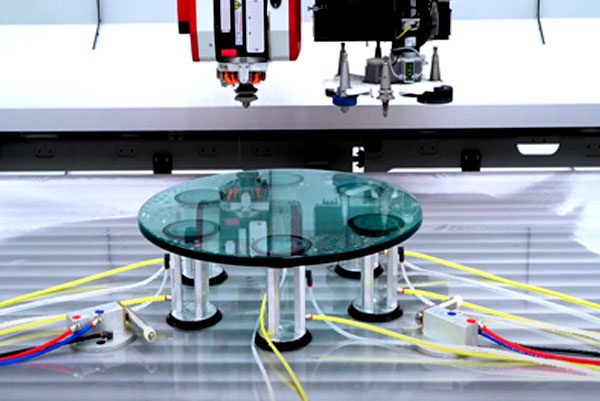

Precision Laser Head – Ensures consistent quality across every piece.

-

Low Maintenance – Reliable design minimizes downtime and servicing needs.

Technical Specifications

- Maximum Processing Size: 3000mm x 1500mm

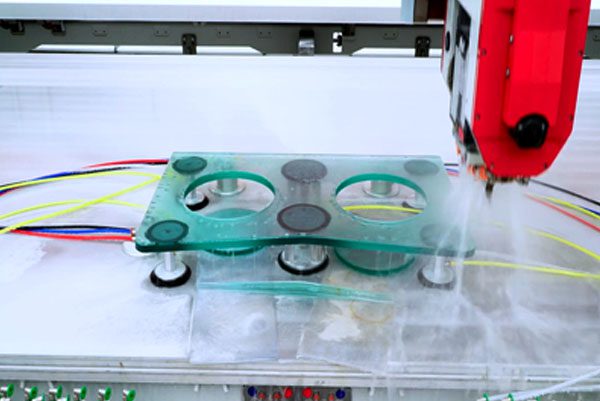

- Processing Thickness: 3mm – 25mm

- Spindle Power: 9kW

- Processing Speed: 0 – 12 meters/minute

- Positioning Accuracy: ±0.02mm

- Control System: CNC numerical control system

- Cooling System: Water cooling

Glass Laser Multi-functional Machine – Precision, Power, and Performance

The Glass Laser Multi-Functional Machine is an advanced solution for high-speed, high-precision engraving and marking on glass and other materials. Designed for efficiency and versatility, this machine delivers consistent, fine dot engraving—making it ideal for producing LED mirrors, decorative glass panels, signage, and more.

With a focus on speed and energy efficiency, the system can process an LED mirror in just 2–3 minutes while consuming only about 1kW per hour, significantly reducing time, labor, and operational costs. It’s a powerful tool for manufacturers and workshops looking to improve output without sacrificing quality.Key Advantages

-

High-Speed Performance

Processes glass surfaces rapidly, cutting production time and boosting efficiency. -

Low Energy Consumption

Uses approximately 1kW per hour, making it highly cost-effective for daily operations. -

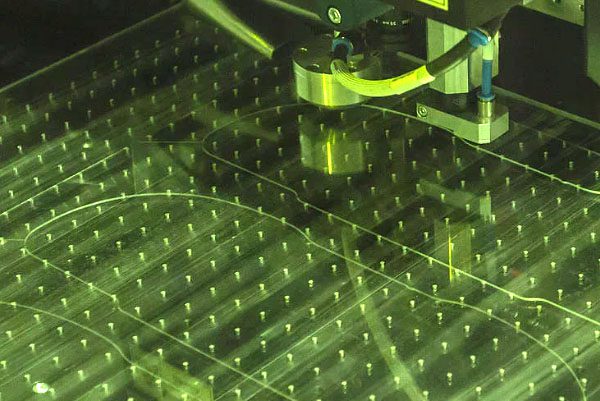

Fine Dot Engraving

Produces detailed and uniform laser marks, ideal for premium glass products. -

Multi-Material Capability

Works on glass, mirrors, and select metals, expanding its use across industries. -

Reduced Labor Costs

Fast operation and automation lower the need for manual handling and supervision.

Why Choose the Glass Laser Multi-Functional Machine?

If you're in the glass manufacturing, interior design, or signage industry, this machine offers a powerful upgrade. Its speed, precision, and low running costs make it ideal for mass production or custom work. Whether you're engraving logos, patterns, or functional designs, the Glass Laser Machine delivers professional results with every pass.

Technical Parameter

| Laser Power | 140W |

| Total Power | 6KW |

| Laser Lifetime | Around 80000hours |

| Max Processing size | 1200*1600mm |

| Voltage | 380V 50-60HZ |

| Cooling Type | Water-cooling |

| Motion Type | 5 Axis Linkage |

| Working Mode | Laser Pulse |

| Laser Center Wavelength | Around 1065 |

| Laser Preheating Time | one min |

| Theory Max Speed | 25000-30000dot/sec |

| Spot Diameter | 6-8mm |

| Frequency Range | 50-170KHZ |

| Total weight | Around 1000kgs |