The Best Glass Door Beveling Machine for Your Business 2025

2025/05/17 By admin

What is a Glass Door Beveling machine?

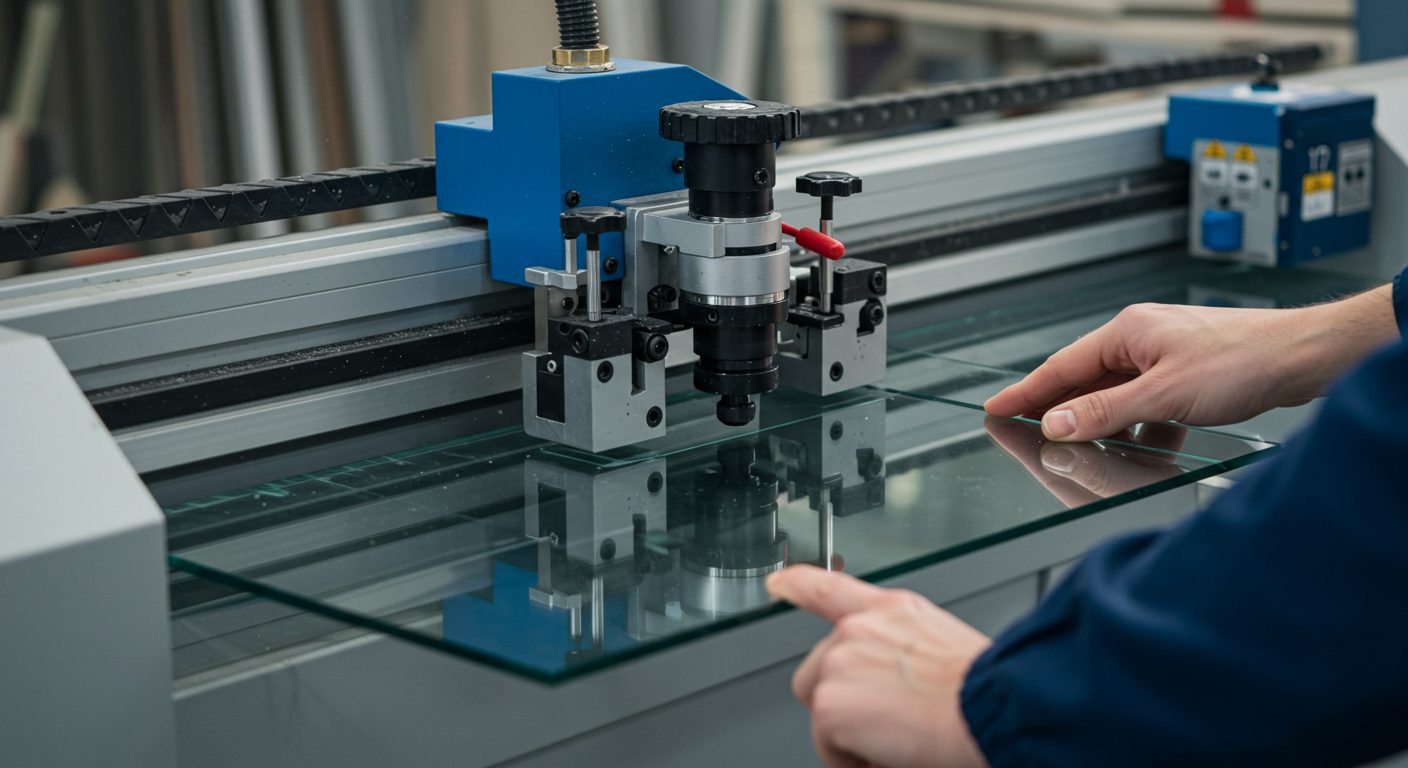

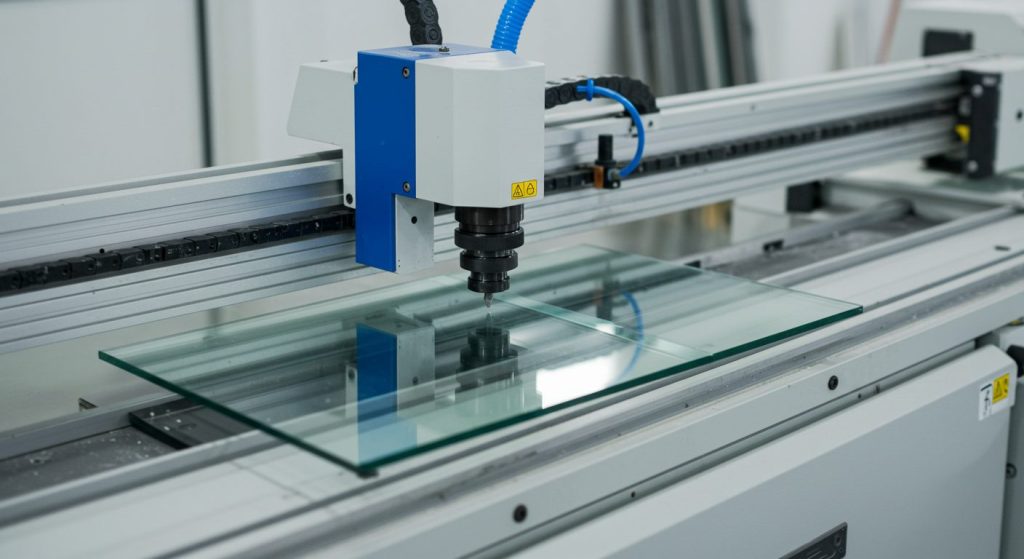

A glass door beveling machine is, in broad terms, a piece of equipment that should never go unnoticed. One of its capabilities is to handle the beveling of glass doors, windows, and other glass pieces. Glass beveling is the process of making a glass piece’s edges smoother and not purely for aesthetic reasons.

Glass Door Beveling Machine: The Ultimate Guide for Precision and Quality

In a protective frame structure, a glass beveling machine is assigned to the protective glass doors. Like any industry, the glass processing industry operates on accuracy. Therefore, this artifact aims to explain the various types and technical parameters of glass beveling machines, along with how to pick the optimum one for your business.

Important Considerations for a Glass Door Beveling Machine

Many different factors must be analyzed to fulfill the business requirements for a glass door machine. Some of the very important factors are discussed below.

- Precision and Accuracy

For uniformity in production, a glass beveling machine needs to have a CNC glass beveling system that can execute bevels at specific angle settings. Custom angle beveling machines are also suitable for intricate and custom designs.

- Speed and Efficiency

Productive output is directly linked to the glass beveling machine’s rate of operation, as productivity is enhanced with faster operations. For businesses with greater demand, the investment should be made towards purchasing high-speed machines, especially those with multi-functional configurations, as these make productivity soar.

- Durability and Build Quality

Every glass beveling machine is designed for different forms of glass. That said, performance and a machine’s lifetime dominate the aspects of structural resilience and longevity of the equipment. Switching to industrial-grade glass beveling machines is strongly suggested as these are built from superior-grade materials fabricated to withstand constant, intensive workloads while maintaining consistent output.

- Polishing Capabilities

The efficiency of polishing machines has increased considerably owing to the simultaneous processes of glass cleaning and beveling. Therefore, clients who require work pieces with an exceptional showroom finish will benefit from glass door beveling and polishing machinery.

Potential Uses of the Glass Door Beveling Machines

These machines have practical applications in:

• Manufacturing of Glass Doors: With the glass door beveling offset machines, doors can be processed to achieve high beauty and functionality.

• Architectural Works of Art glass: Major architectural glass works include edge finishing, which should be smoothed out to eliminate the likelihood of sharp edges of glass after installation.

• Glasses in Furniture: Edge beveling is needed to make the glass panels of a piece of furniture attractive. It is the purpose of some furniture glass beveling machines.

• Processing of Mirrored Glass Edges: Mirrored glass edges are processed just like glass edges, except mirror beams are used to do the beveling.

Construction Business Specifics and Their Purpose

A range of other business processes specifies unique features that serve custom purposes. Determine the volume of glass doors to be beveled and production speed increase on other processes, so that other requirements can also be integrated. Find out the value of a glass door beveling machine tailored to serve all types of businesses. Develop a suitable business profile along with Glassdoor production goals.

- Determine the Needed Set Accuracy

For particular assignments, seek out beveling CNC machines as they will compensate for any inaccuracies. These machines are extremely accurate as the design is offset.

- Specify Glass Sheets Measurement

Miter Vertical Saws determine the dimensions and the weight of the glass doors or glass panels. Vertical beveling machines are best suited for longer panels, while horizontal machines excel with small sheets.

- Search for Other Additions

Select a performing engraver that polishes automatically after the last bevel if the window needs polishing at the final stage. This way, time is conserved, and polished glass is still attained.

Maintenance and Care of Glass Doors Beveling Machines

Proper upkeep of the glass beveling device requires the proper routine maintenance of glass beveling machines. Recommended policies for glass beveling tools are, in brief, the following.

- Prevent dirt from accumulating in the machine due cleaning.

- Check spindles and grinding wheels for activity.

- Moving parts must be lubricated.

- In these parts, the lowering requires constant attention.

Premium Glass Door Beveling Machine From Baineng

The team at Baineng is pleased to introduce you to the Beveling Machine for Glass, a masterpiece in edge finishing that enhances glass doors. These glass beveling machines operate at exceptional speeds, achieving incredibly smooth running and spindle bevel accuracy. Most importantly, productivity is enhanced with glass beveling machines.

What Features Glass Door Beveling Machine Make it Stand Out Better, Prioritizing Speed Over Competitors?

With the ability to perform 3mm to 19mm bevels on glass sheets, the machine performs sharp bevels professionally. This includes multi-angle edge cutting and fine polishing. Each action is accomplished with precise straight-line beveling.

- Competency in the Contemporary Glass Industry

The machine excels in architectural glass fabrication. It can produce decorative glass panels, as well as doors and mirrors. The machine enhances the aesthetic, safety, and quality of the glass. Baineng, known to be energy conservative, has innovative structures and factories, proving to the world they can trust the double glass door beveling machine precision coupled with reliability. The machine itself is beautifully constructed to last. We also provide an expansive search that resolves your search for all other glass-processing equipment.

- Cost Analysis of Glass Door Beveling Devices

About glass door beveling devices, the area of cost variation is influenced by the number of heads/spindles, device classification: automatic or CNC, and the presence of added polish and chamfering. From my estimates, prices for the machines begin from $5000 to 50000 for the least costly options, then to unlimited amounts for the top tier machines.

Conclusion

In seeking a streamlined model of business operation in the glass industry, it entails adding a value process of installing a glass door beveling unit that interfaces edges for easing actuation while smoothing down the edges. Products include, but are not limited to, an automatic glass door beveling machine, CNC glass door bevelers, and multi-head machines. Proper use of tools and good upkeep will, without a doubt, guarantee improved operational efficiency. BAINENG encourages you to get in touch with us for any additional inquiries or professional expertise related to glass beveling machines.

TRENDING POSTS

- Glass Shape Edging Machine Product Solution 2025/05/17

HOT TOPIC

- architectural glass beveling machine

- automatic glass beveling machine

- Automotive Glass Beveling Machine

- cnc engraving machine manufacturer

- CNC glass beveling machine

- cnc glass edge polishing machine

- CNC glass grinding machine

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machining Center

- decorative glass beveling machine

- glass beveling and polishing machine

- glass beveling equipment

- glass beveling machine distributor

- glass beveling machine for sale

- glass beveling machine manufacturer

- glass beveling machine price

- glass beveling machine supplier

- glass door beveling machine

- glass edge beveling machine

- glass edge chamfering machine

- glass edge finishing machine

- glass edge grinding machine

- glass edge polishing machine

- glass edge processing machine

- glass edge shaping machine

- glass edge smoothing machine

- glass edge trimming machine

- glass furniture beveling machine

- glass panel beveling machine

- Glass Shape Edging Machine

- glass window beveling machine

- mirror beveling machine