Understanding Glass Edge Processing: Machines and Techniques

2025/05/20 By admin

The Definitive Guide to Glass Edge Processing Machines: Varieties, Uses, and Innovations

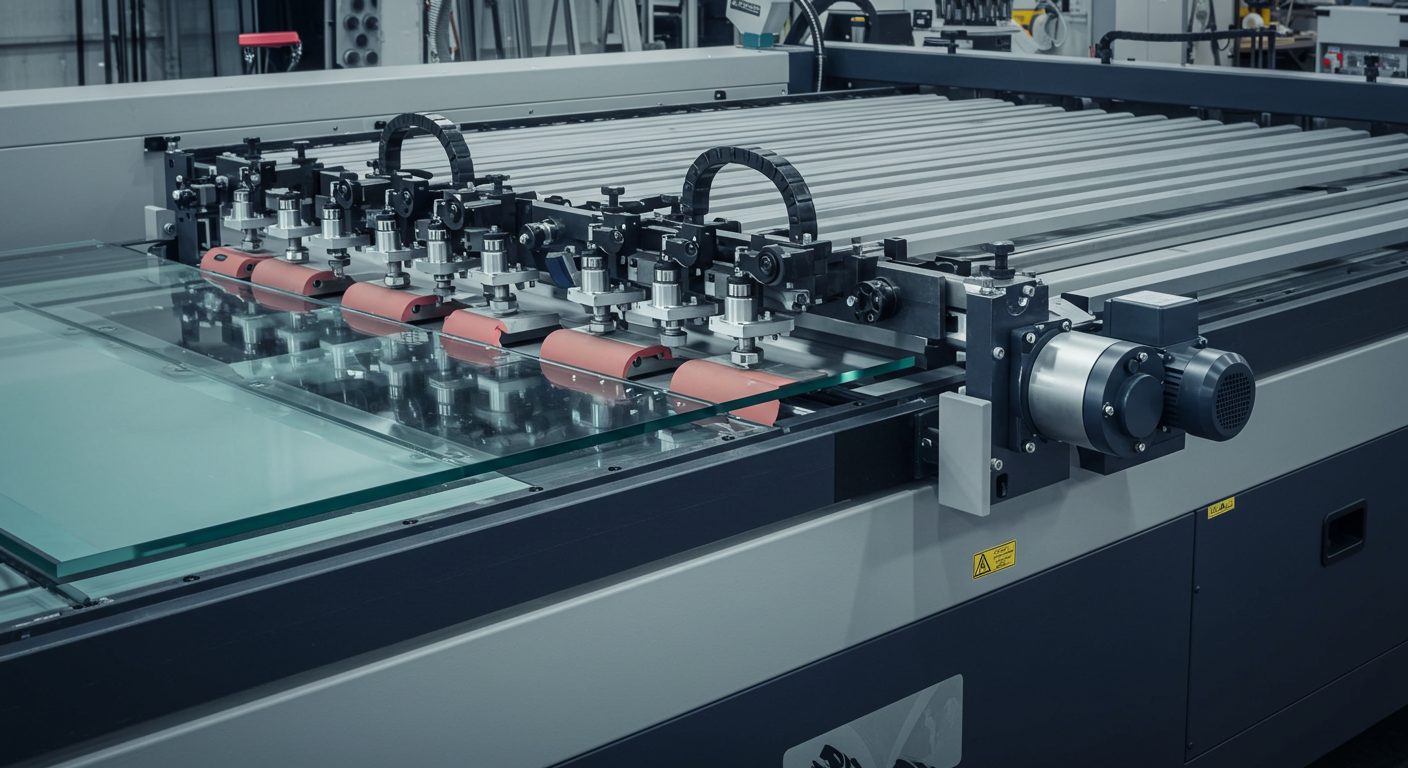

As far as tools used in the processing and fabrication of glass, the glass edge processing machine plays a fundamental role in providing a critical measure of safety as well as a good polish to glass products. The finishing done on the edges must be standard on everything, ranging from sophisticated architectural panels to complex decorative objects. This guide is dedicated to the study of glass edge processing machines – their types, applications, and emerging technologies.

Glass Edge Processing Machines: Definition & Features

Fundamentally, glass edge processing machines serve the purpose of refining glass sheets by improving their safety, durability, and aesthetics. Every piece of glass prepared for any use must fulfill functional and beauty muster. However, glass needs to undergo various stages of preparation (grinding, chipping), so glass edge finishing machines must eliminate sharp edges and any micro-cracks.

Edge Finishing Techniques for Glass: Safety Meets Aesthetics

In every stage of glass edge processing, the completion of the edge bears no less significance than the preliminary steps. It must not only please the eye, but it should also make the glass durable and effectively suitable to undergo some other processing, such as tempering, lamination, or bonding. Typically, these are some of the techniques applied in glass edge finishing:

• The most widespread technique of producing smooth, glossy edges.

Polished Flat

Commonly applied in the design of interiors, furniture, and displays, flat polished edges demonstrate an exquisite clarity and professionalism. Flat, polished edges are formed through the use of fine diamond wheels and polishing tools.

– Beveling: This is the additional refinement and depth-enhancing treatment of mirrors. Glass slabs and mirrors can be processed by cutting their outer edge at 45 45-degree angle. Beveling adds mirroring to some extent, which makes depth vistas stand out visually.

– Arrissing (Seaming): Removing the sharpness of cut glass edges is what arrissing accomplishes. This process is more to do with safety, for the most part, and is usually a process of glass tempering pre-treatment. It removes stress points and micro-cracks, which makes glass break easily.

– Pencil Edging: Pencil edging yields a rounded, soft edge typical for tabletops, shelves, and frameless glass. The name comes from its profile, which resembles a pencil. It is common practice where users are likely to come into contact with the glass.

– Mitering: This process is useful for glass-to-glass corners, as it entails slicing the glass edge at particular angles, often 45 degrees. Mitering guarantees tight, seamless joints for the shower enclosures, cabinets, and glass structures.

All of these procedures require selection based on safety features, visibility, and the purpose of use.

Industrial Applications

Different sectors utilize glass edge processing machines, including:

• Construction: For curtain walls and partitions as well as facades, where both beauty and strength are critical.

• Fabrication: In the production of tabletops, shelves, and other decorative items, where edges contribute to the elegance of the polished pieces.

• Transportation: Processing safety glass for windshields and windows to comply with legal and industry standards regarding safety and visual appeal.

• Industrials: Used on glass components such as oven doors and refrigerator shelves that require a high-quality edge finish.

• Optical: Glasses mirrors need the surface to be finely edged in order to enhance reflection and be smoother for safety.

Current Developments of Technology in Glass Edge Processing Machines

The speed and precision with which glass edge processing machines operate today are better than ever due to the recent technological advancements in automation and control technology. They not only increase production rate and accuracy but also improve the quality and sustainable practice of glass manufacturing.

• Automation: Full automation is one of the newest technologies to be adopted. Automatic glass edging machines have eliminated the need for operators as everything from loading to edge polishing is accomplished automatically with great precision and attention to detail.

• Advanced Control Systems: Touchscreen control panels, PLCs, and CNC systems come as standard in modern machines. These features enable accurate control of the machine’s rotational speed, the pressure applied, and the edge profiling, ensuring a proprietary finish on different glass types and thicknesses.

• Energy Efficiency: Grinding machines that specialize in glass shards have become prominent because of their sustainable practices. The industry now requires these machines, as they are equipped with specialized motors and intelligent energy systems designed to optimize performance.

• System Integration: It is now possible to connect modern glass working centers with fully automated production lines, allowing for sequential processing from cutting to final polishing. This increases the overall output while decreasing the operating costs and is particularly beneficial for architectural and automobile glass.

Modern edge processing machinery is a smart investment for efficient, eco-friendly, and high-quality glass fabrication.

Maintenance and Safety Considerations

Proper maintenance guarantees the overall functionality and promotes the lifespan of glass edge processing machines.

• Routine Checks: Examination of grinding wheels and belts, among other parts, to check if they are functioning and free of damage.

• Lubrication: Moving parts must be lubricated adequately to lower friction-induced damage.

• Cleaning: Cleaning glass particulates and dust enhances visibility and prevents contamination.

Safety always comes first. Operators must receive training, and machines must have emergency stop buttons, protective guards, and written instructions outlining what to do and what not to do in a safety-sensitive environment.

How to Select a Suitable Glass Edge Processing Machine

It is vital to analyze your business’s operational processes when purchasing the best glass edge processing machine. The correct selection for your business can dramatically improve the operational efficiency, product quality, and profitability of your business. Here are some considerations:

• Production Volume: High-output facilities should consider CNC glass edge processing machines or double edging machines as these ensure maximum throughput and precision. Such machines are ideal for problematic repetitive bulk industrial manufacture with constant, large-scale processing and minimal downtime.

• Glass Types: Various machines perform optimally on certain types of glass. If you are working with thick architectural panels, delicate mirrors, or more complicated geometric shapes, ensure your machine can manage the glass thickness, dimensions, and complexity required by your projects.

• Desired Edge Finish: If your applications include specific edge treatments such as flat polishing, beveling, or pencil edging, these edge treatments will need to be performed on a machine designed for those processes. For instance, mirrors and decorative glass would require a glass beveling machine, while safety edge treatment would require the use of arrising machines.

*Investment Limitations*: Besides considerations such as budget and expected returns associated with the purchase of high-end equipment, the operational expenditures linked to the servicing, maintenance, and energy consumption over time also need to be factored in to evaluate the overall savings.

If you are looking for trustworthy and precise suppliers for glass edge processing, Bai Neng Machinery is your advanced glass machinery provider.

Conclusion

Machines for grinding the edges of glass are of remarkable importance in contemporary processing as they ensure that products are not only safe but also visually pleasing. By taking into account the types and application range as well as the new developments in these machines, companies could make better choices, which would improve their productivity in processing glass.

TRENDING POSTS

- Glass Shape Edging Machine Product Solution 2025/05/20

HOT TOPIC

- architectural glass beveling machine

- automatic glass beveling machine

- Automotive Glass Beveling Machine

- cnc engraving machine manufacturer

- CNC glass beveling machine

- cnc glass edge polishing machine

- CNC glass grinding machine

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machining Center

- decorative glass beveling machine

- glass beveling and polishing machine

- glass beveling equipment

- glass beveling machine distributor

- glass beveling machine for sale

- glass beveling machine manufacturer

- glass beveling machine price

- glass beveling machine supplier

- glass door beveling machine

- glass edge beveling machine

- glass edge chamfering machine

- glass edge finishing machine

- glass edge grinding machine

- glass edge polishing machine

- glass edge processing machine

- glass edge shaping machine

- glass edge smoothing machine

- glass edge trimming machine

- glass furniture beveling machine

- glass panel beveling machine

- Glass Shape Edging Machine

- glass window beveling machine

- mirror beveling machine