What is a Glass Panel Beveling Machine? Types & Applications

2025/05/17 By admin

Definition of Glass Panel Beveling Machines

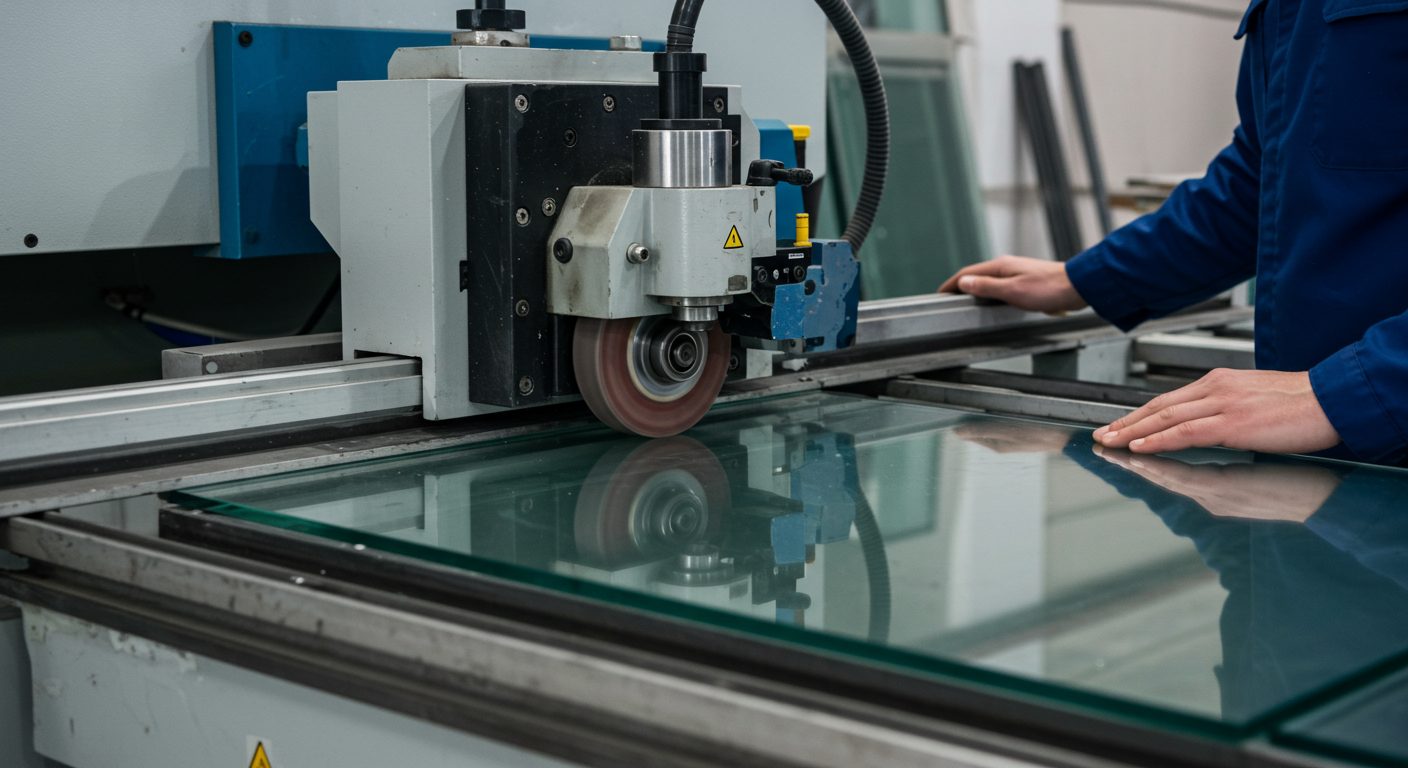

Step by step, a glass panel beveling machine makes a glass panel by creating and smoothing each glass side with refined detail, to a pleasing silky finish. It is a procedure involving the roughening and the melting, and subsequently the smoothing of decorative finishes to the edges of glass pieces. Such machines are vital in the glass machining industry due to the profitability of precision and aesthetic quality of the finished work.

Explanation of Glass Panel Beveling Machines

Polishing glass surfaces is eminent in the realm of construction and interior decoration, and rich in refinement. One of the monumental advancements for specialists is the glass beveling machine. From furniture and mirrors to architectural façades, doors, and windows, the beauty and utility of beveled glass panels are unrivaled. In the following section, we will discuss the working mechanisms of glass panel beveling machine and its multifunctional uses, including selection parameters.

Some of the beveling machine applications are as follows:

• Mirror installations

• Fabrication of serving and making tables

• Window panes cutting

• Glass door fabrication

• Architectural glass panels making

• Decorative glass cutting and engraving

Operational Features of Glass Beveling Machines

1. Most machines let you work with bevel angles ranging from 0 to 45°.

2. The glass thickness compatibility depends on the machine model, and it ranges from 3mm to 25mm.

3. The processing speed of glass edges is dependent on the speed of the spindle and conveyor, which are adjustable.

4. For repetitive precision tasks, CNC and PLC are available.

5. Machines can have an additional ten to twelve spindles for dusting off and polishing the workpieces.

6. The use of integrated water circulation systems helps to prevent overheating and cool the machine.

Glass Beveling Machines Differentiation

Having different kinds of machines ensures appropriate decisions:

1. They can be Straight Line Glass Beveling Machines

• Accomplishes complicated edge beveling with a straight line.

• Ideal for high-volume production.

2. Curved Glass Beveling Machines

• Finishes beveling custom-cut glass with irregular contours or complex outlines.

• These find applications in furniture and decorative art.

3. CNC Glass Beveling Machines

• Fully automated.

Operated by the use of a computer system.

• Designed for very detailed patterns and precise work.

Applications of a Beveling Machine in Different Sectors

1. Furniture Manufacturing

• Beveled glass enhances the beauty of table, cabinet, and shelf tops.

2. Architectural Glass Work

• Beveled window panes and decorative facades enhance the beauty of the building.

3. Interior Design of Buildings

• Bevelled mirrors and wall panels adorn the room, giving an illusion of more space and luxury.

4. Automotive

• Beveled decorative glass is scarce in top-range vehicles.

The Beveling Process: Simple Step-by-Step Guide

1. Receiving glass panels into the system: The glass panels are dropped into the conveyor belt system.

2. Contouring: The glass borders are rounded with diamond-edged wheels.

3. Shaping: Angled edges are shaped by several grinding spindles.

4. Final polishing: Felt and resin wheels are used for the finishing felt or resin wheels.

5. Quality check: The final check is a very careful one for finishing and precision angles.

Benefits of an Automatic Glass Beveling Machine

- Accurate Measurement

Today’s technology permits the automated engraving of each edge of glass, such as mirrors and furniture pieces, ensuring the bevels and edges for sophisticated glass parts are accurately measured alongside the angles checked for precision.

- Uniform Standards

Every piece of glass is subjected to the same actions in automated machines, which guarantees uniformity in bevel width and angle in terms of finish for copies of the same unit. This reduces the amount of defects and rework needed.

- Time Efficiency

The time to process glass with automatic machines is significantly less compared to manual work. The use of high-speed motors and synchronized lines improves throughput, which is ideal for bulk orders.

- Easy to Operate

Modern beveling machines come with touch screen interfaces that have up-to-date software. Thus, setting parameters, monitoring activities, and correcting inaccuracies becomes easier, which reduces mistakes and training time.

- Reduced manual labor requirements

With these machines, intricately hands-on tasks become automated. This also allows one operator to operate more than one machine, reducing the cost of operations while enhancing efficiency and productivity.

Factors to Consider When Choosing a Glass Beveling Machine

1. If the output is high in volume, consider high-speed or double-edge models.

2. Temper, laminate, or flat glass needs to be checked for compatibility.

3. Depends on the workspace and the size of the glass pane.

4. CNC and PLC control systems are more suited if the focus is on industrial accuracy and automation.

5. Reputable manufacturers of glass beveling machines with reputable after-purchase service should be sought.

Routine Repairs and Maintenance of Glass Beveling Machines

Noted spindles and polishing wheels are part of the components that are often neglected but can provide or create uneven glass surface edges. Through use, the polishing wheels and spindles can become misaligned or worn. Regular inspections not only guarantee the desired finishing quality but also help in averting uneven bevels. All worn parts must be replaced to ensure the desired results.

- Water Circulation System Maintenance

During glass cleaning in the course of beveling work, there must be an uninterrupted flow for both cooling and cleansing. An inefficient water circulation system can hurt the productivity of the system and even cause physical damage. To avoid overheating, the smooth action of the device’s parts is essential, thus requiring the regular cleaning of filters, pipes, and tanks.

- Lubrication of Moving Parts

Other working parts, like guides, belts, and bearings, are subject to daily wear due to the circular motion. Recommended lubrication intervals must be followed to reduce friction and extend the machine’s lifetime.

- Perform Updates as Required

Beveling machines with CNC or PLC controls require attention regarding software updates. Productivity is increased via firmware change as it improves reliability, responsiveness, and the ability to work with modifications.

- Monitor Alarms and Errors

As to the Beveling glass machine, its error checking capability is done in real time. Make sure to react to the alarm signals within the bounds of the user manual and reach out to the support team for the steps needed for proper diagnostics.

Best Practices When Operating Glass Beveling Equipment

- Use the proper personal protective equipment, such as goggles, gloves, a mask, and other protective clothing.

- Put in place a preventive maintenance check before the production run.

- Educate all operators on the functions of the machine.

- Ensure that the glass material is of high quality to prevent excessive chipping of the edges.

- Monitor the feed rate constantly to maintain a uniform bevel.

Primary Features of Concern in a Beveling Machine

• Action Limit Safety Switches

• Manual and Automated Function

• Multi-Angle Welding Capability

• Smart Touch Screen Controller

• Automatic Edge Sensors for Variation in Glass Thickness

• Dual Side Processing Capability

• Glass Thickness Auto Sensing Measurement from Upper and Lower Limits

• Integra Interlock Safety System Made in Taiwan

Reasons Why You Should Use Bai-Neng for Your Glass Beveling Needs

We, at Baineng, address your glass processing issues quite effectively. Our industrial glass beveling machines are simple yet accurate and tough. From low-capacity workshops to high-volume producers, we offer flexible solutions for all. Check our newest products:

• Automatic Glass Beveling Machine

• CNC Glass Beveling Machine

Conclusion

The glass panel beveling machine has wide-ranging operations. Whether it is high-speed production for glass panel edging with intricate detailing, there exists a machine for the same. A timely investment can improve the quality of work and speed of work. Contact BAINENG for an upgrade on the standards of equipment you expect for your glass beveling task. As of now, the routine glass panels can be transformed into stunning masterpieces effortlessly.

TRENDING POSTS

- Glass Shape Edging Machine Product Solution 2025/05/17

HOT TOPIC

- architectural glass beveling machine

- automatic glass beveling machine

- Automotive Glass Beveling Machine

- cnc engraving machine manufacturer

- CNC glass beveling machine

- cnc glass edge polishing machine

- CNC glass grinding machine

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machining Center

- decorative glass beveling machine

- glass beveling and polishing machine

- glass beveling equipment

- glass beveling machine distributor

- glass beveling machine for sale

- glass beveling machine manufacturer

- glass beveling machine price

- glass beveling machine supplier

- glass door beveling machine

- glass edge beveling machine

- glass edge chamfering machine

- glass edge finishing machine

- glass edge grinding machine

- glass edge polishing machine

- glass edge processing machine

- glass edge shaping machine

- glass edge smoothing machine

- glass edge trimming machine

- glass furniture beveling machine

- glass panel beveling machine

- Glass Shape Edging Machine

- glass window beveling machine

- mirror beveling machine